custom medical mold services

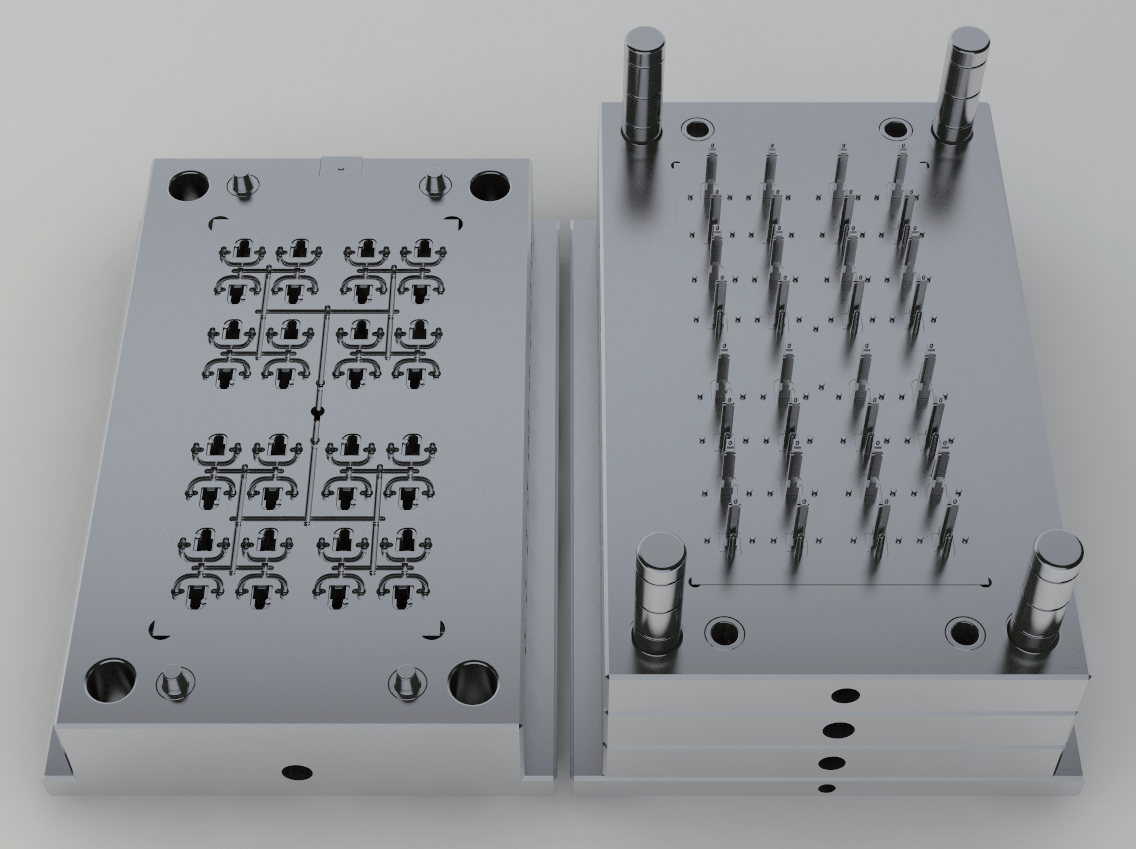

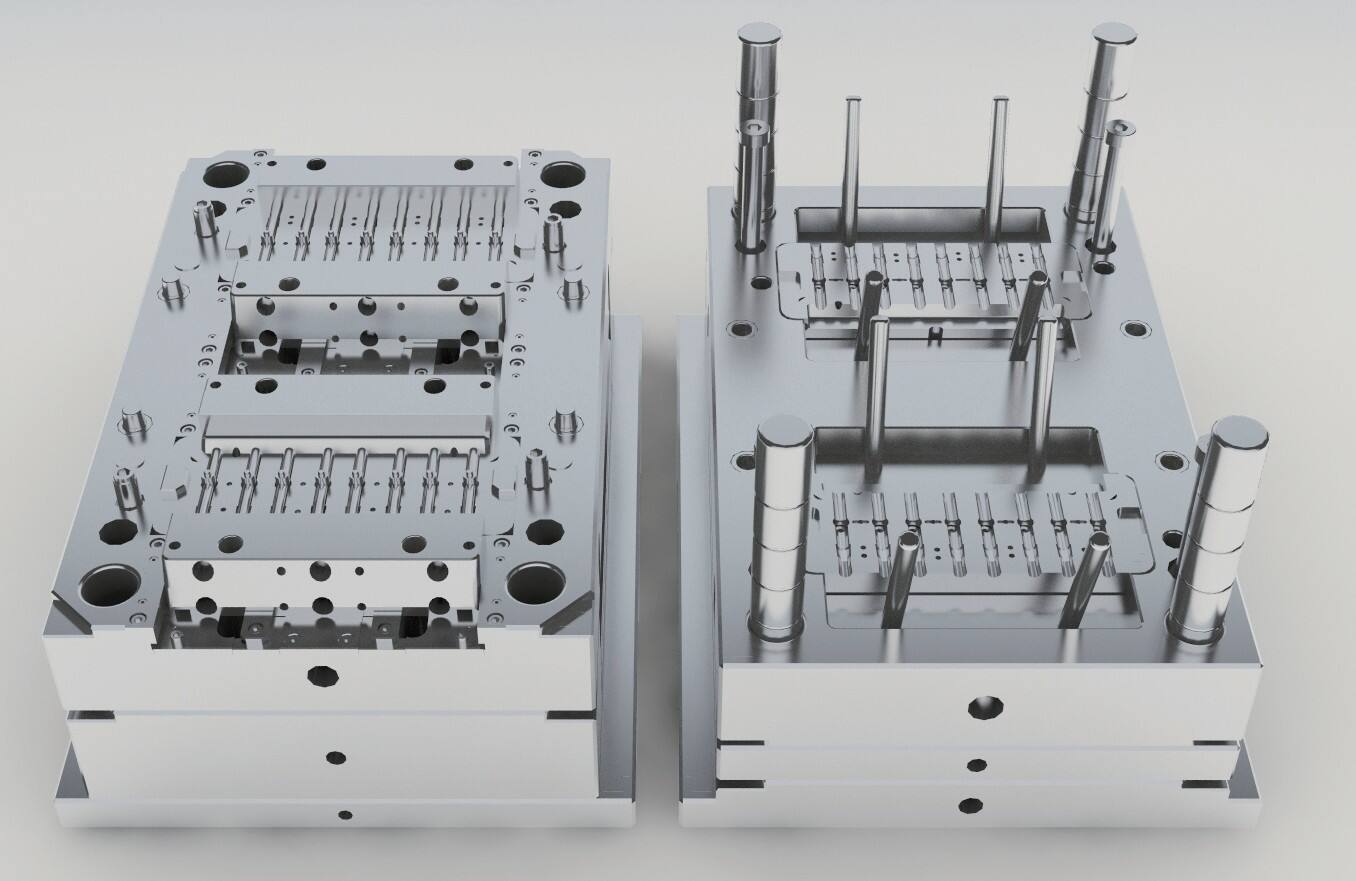

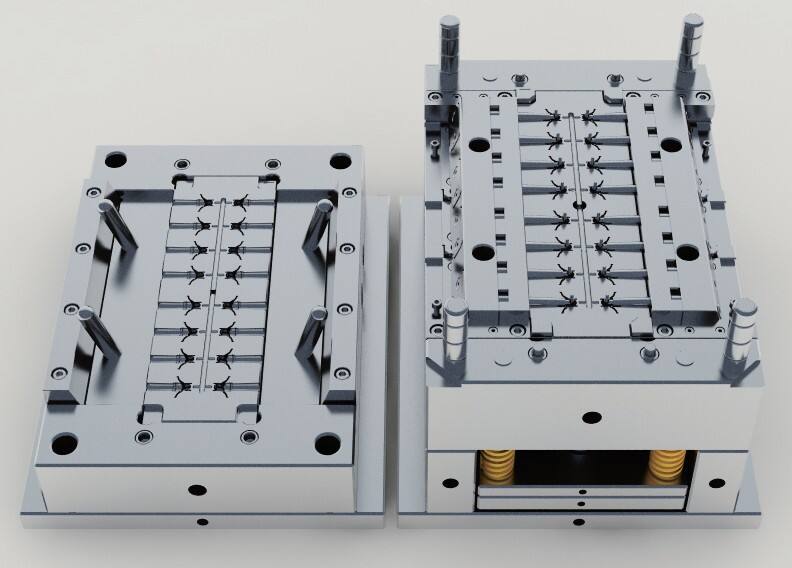

Custom medical mold services represent a crucial component in modern healthcare manufacturing, offering precision-engineered solutions for producing medical devices, components, and equipment. These specialized services combine advanced CAD/CAM technology with state-of-the-art manufacturing processes to create highly accurate, repeatable molds that meet strict medical industry standards. The service encompasses comprehensive solutions from initial design consultation through prototype development, tooling creation, and final production. Expert engineers utilize sophisticated software and machinery to develop molds that accommodate complex geometries, maintain tight tolerances, and ensure consistent quality in medical product manufacturing. These services are particularly vital for producing specialized medical components such as surgical instruments, diagnostic equipment parts, medical device housings, and various healthcare-related plastic components. The process involves rigorous quality control measures, including cleanroom manufacturing capabilities, FDA-compliant materials selection, and detailed documentation to meet regulatory requirements. Custom medical mold services also incorporate advanced features such as multi-cavity designs, hot runner systems, and automated extraction mechanisms to optimize production efficiency and reduce waste.