mini injection molding

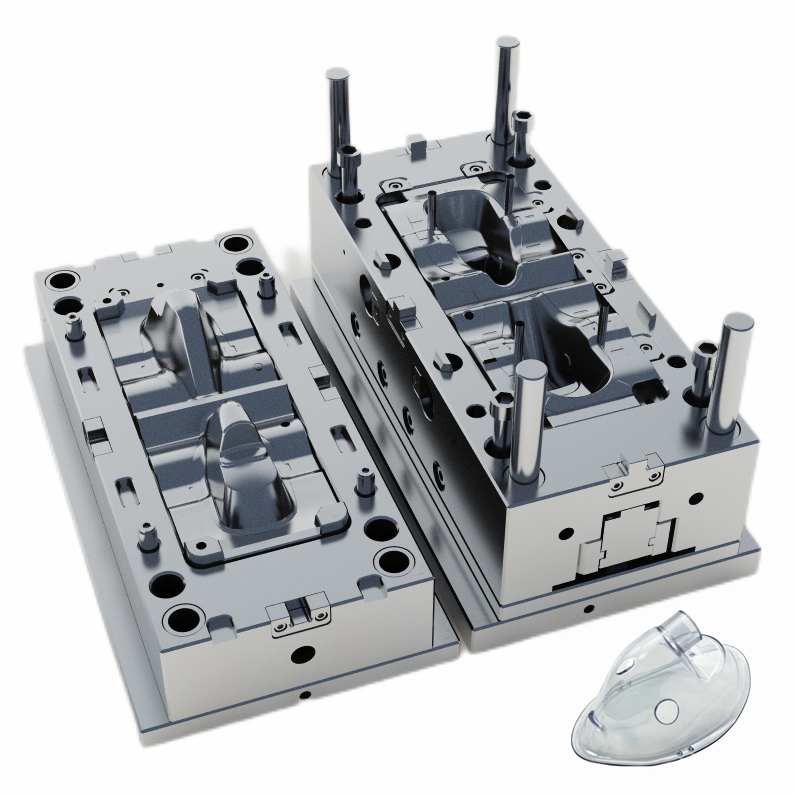

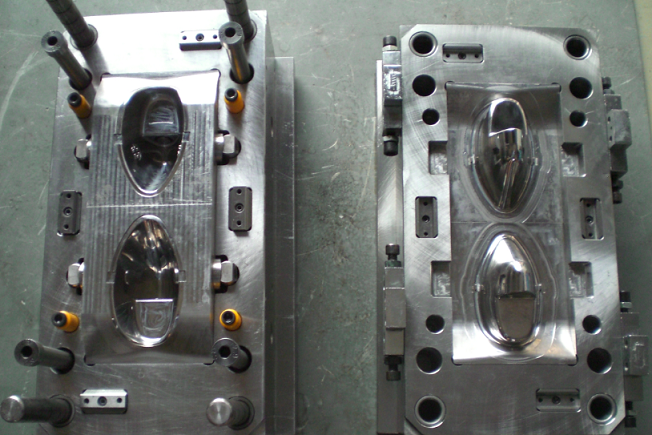

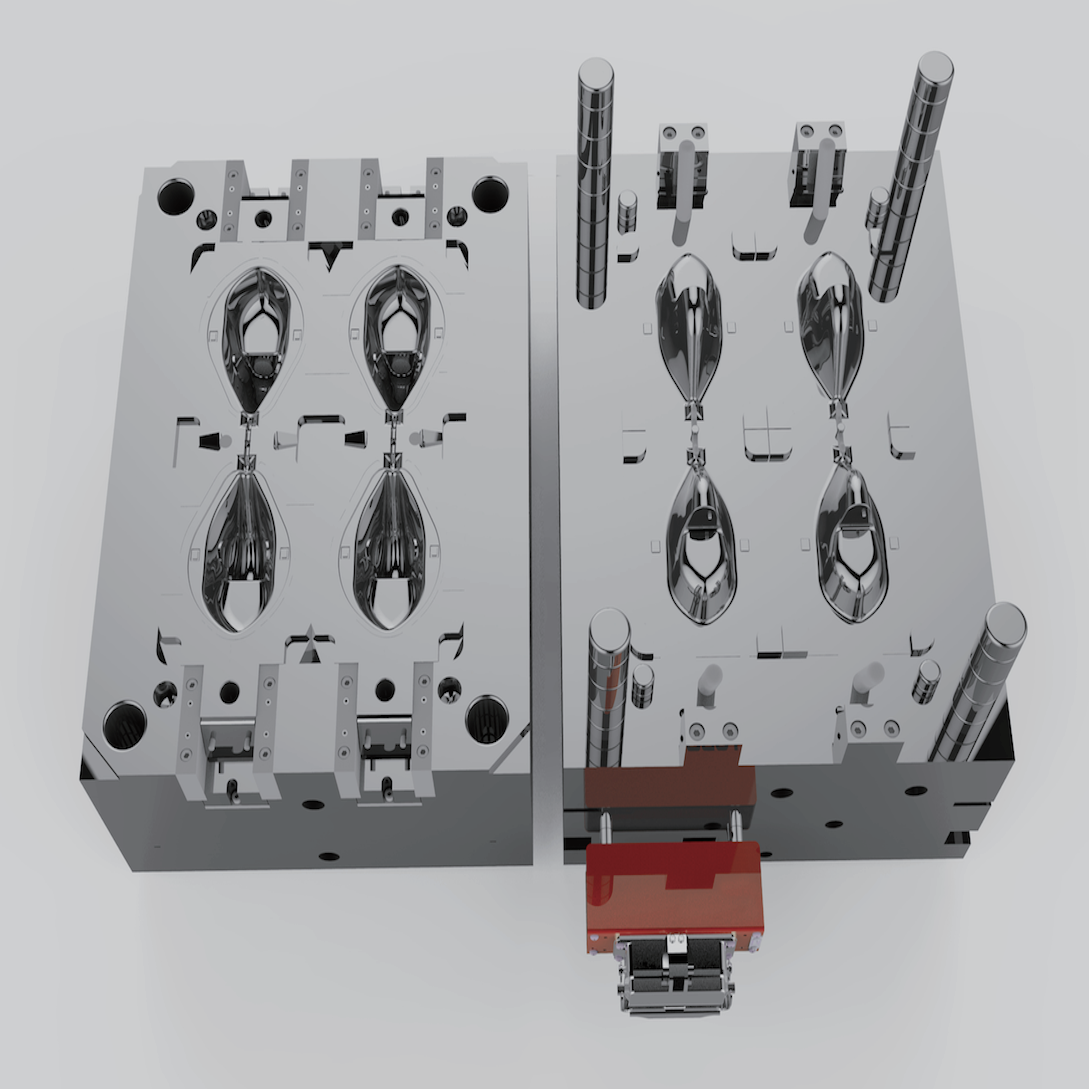

Mini injection molding represents a cutting-edge manufacturing technology that specializes in producing small, precise plastic components with exceptional accuracy. This innovative process utilizes specialized equipment designed to handle shot sizes ranging from less than a gram to several grams, making it ideal for manufacturing micro-scale parts. The technology incorporates advanced control systems that ensure precise material flow, temperature regulation, and pressure control throughout the molding cycle. Mini injection molding machines feature reduced barrel sizes, specialized screw designs, and precise dosing mechanisms that minimize material waste while maintaining exceptional quality standards. The process excels in producing intricate components for industries such as medical devices, electronics, telecommunications, and micro-mechanical systems. What sets mini injection molding apart is its ability to achieve tight tolerances, often within microns, while maintaining consistent quality across high-volume production runs. The technology supports a wide range of engineering-grade polymers and can incorporate advanced features such as micro-texturing, complex geometries, and multi-material combinations. This manufacturing method has become increasingly important in the development of miniaturized devices and components, particularly in applications where precision and reliability are paramount.