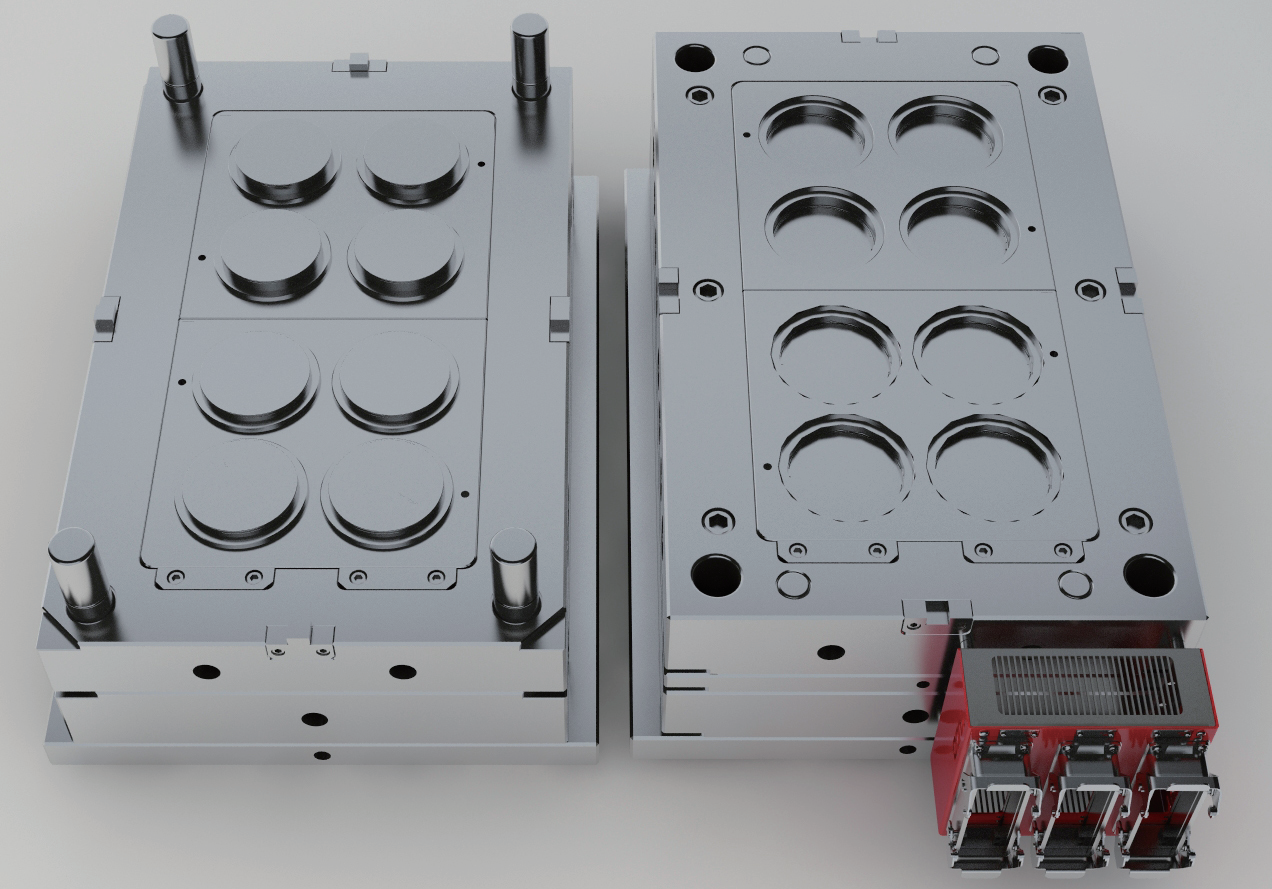

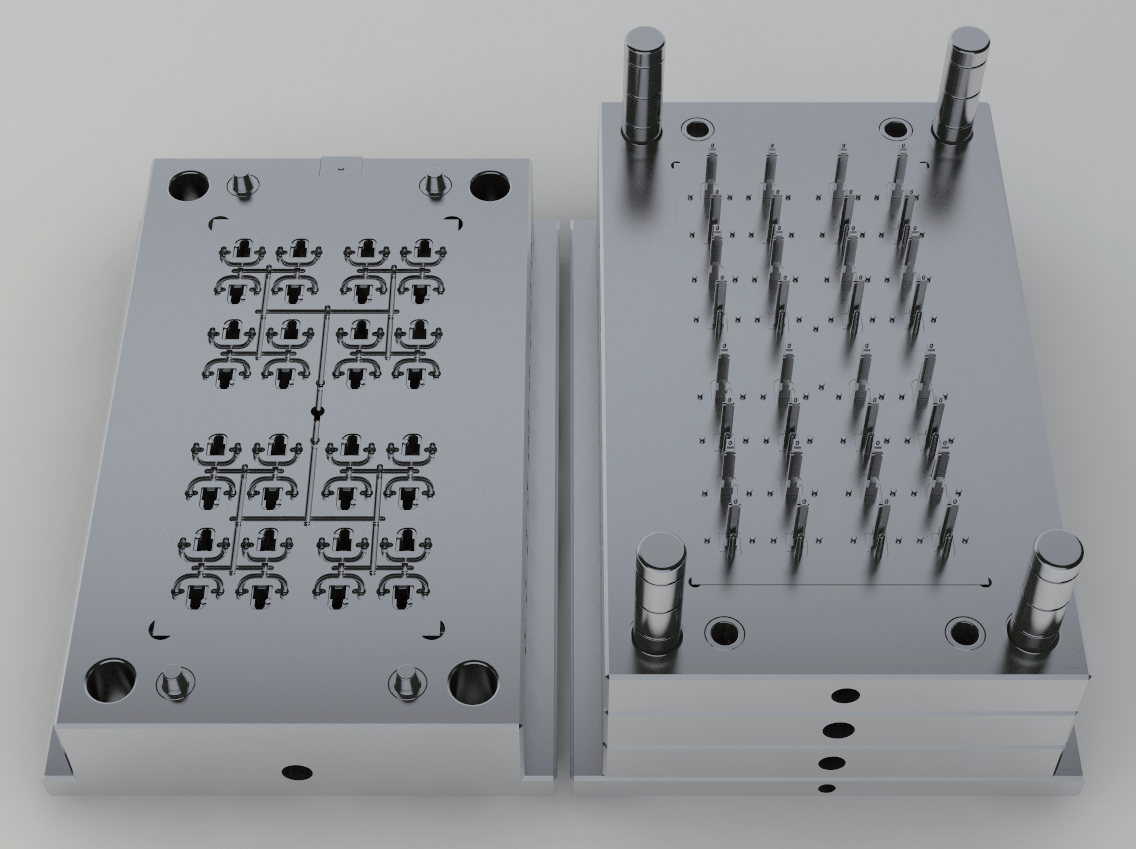

plastic mold maker

A plastic mold maker is a sophisticated manufacturing system designed to create precision molds for plastic component production. This advanced machinery combines cutting-edge technology with precise engineering to produce high-quality injection molds that meet diverse industrial requirements. The system incorporates computer-aided design (CAD) capabilities, allowing for intricate detail work and exceptional accuracy in mold creation. Operating through a combination of mechanical and digital processes, the plastic mold maker utilizes various cutting tools, including end mills, drills, and specialized cutters, to shape raw materials into precise mold components. The machine's advanced control systems ensure consistent quality across production runs, while its multi-axis functionality enables the creation of complex geometrical shapes and patterns. Modern plastic mold makers feature integrated cooling systems, automated tool changing mechanisms, and real-time monitoring capabilities, making them essential for industries ranging from automotive manufacturing to consumer electronics production. The equipment's versatility allows for the production of molds in various sizes and complexities, accommodating both small-batch custom orders and large-scale industrial production needs.