multi injection molding

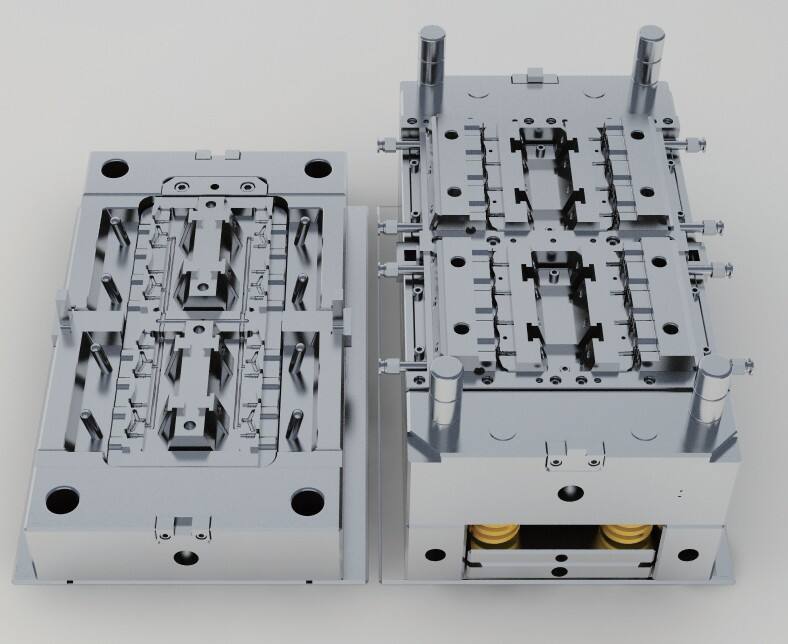

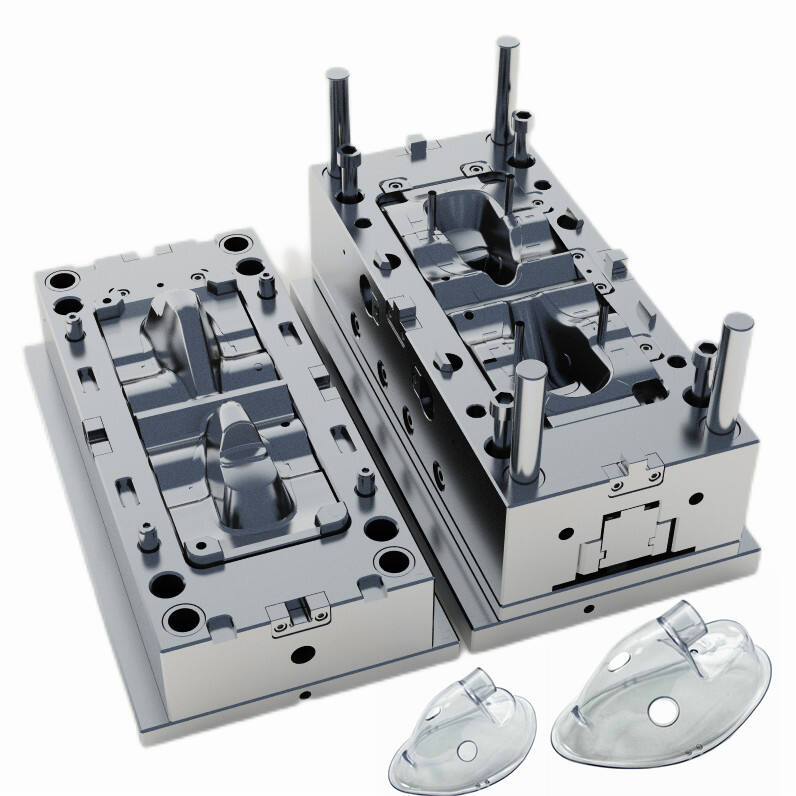

Multi injection molding is an advanced manufacturing process that enables the production of complex plastic parts by injecting multiple materials or colors into a single mold during the production cycle. This sophisticated technology allows manufacturers to create components with varying physical properties, colors, and textures in a single operation. The process involves multiple injection units working in sequence or simultaneously, each delivering different materials into specifically designed mold cavities. This technique eliminates the need for secondary assembly operations and reduces production time significantly. The technology utilizes sophisticated control systems to manage material flow, temperature, pressure, and timing precision, ensuring consistent quality across production runs. Multi injection molding finds extensive applications across various industries, including automotive, consumer electronics, medical devices, and household appliances. It's particularly valuable for creating products that require combinations of hard and soft materials, multiple colors, or different functional properties in different areas of the same part. The process can accommodate a wide range of thermoplastic materials, enabling manufacturers to optimize product design for both aesthetics and functionality.