benchtop injection molding

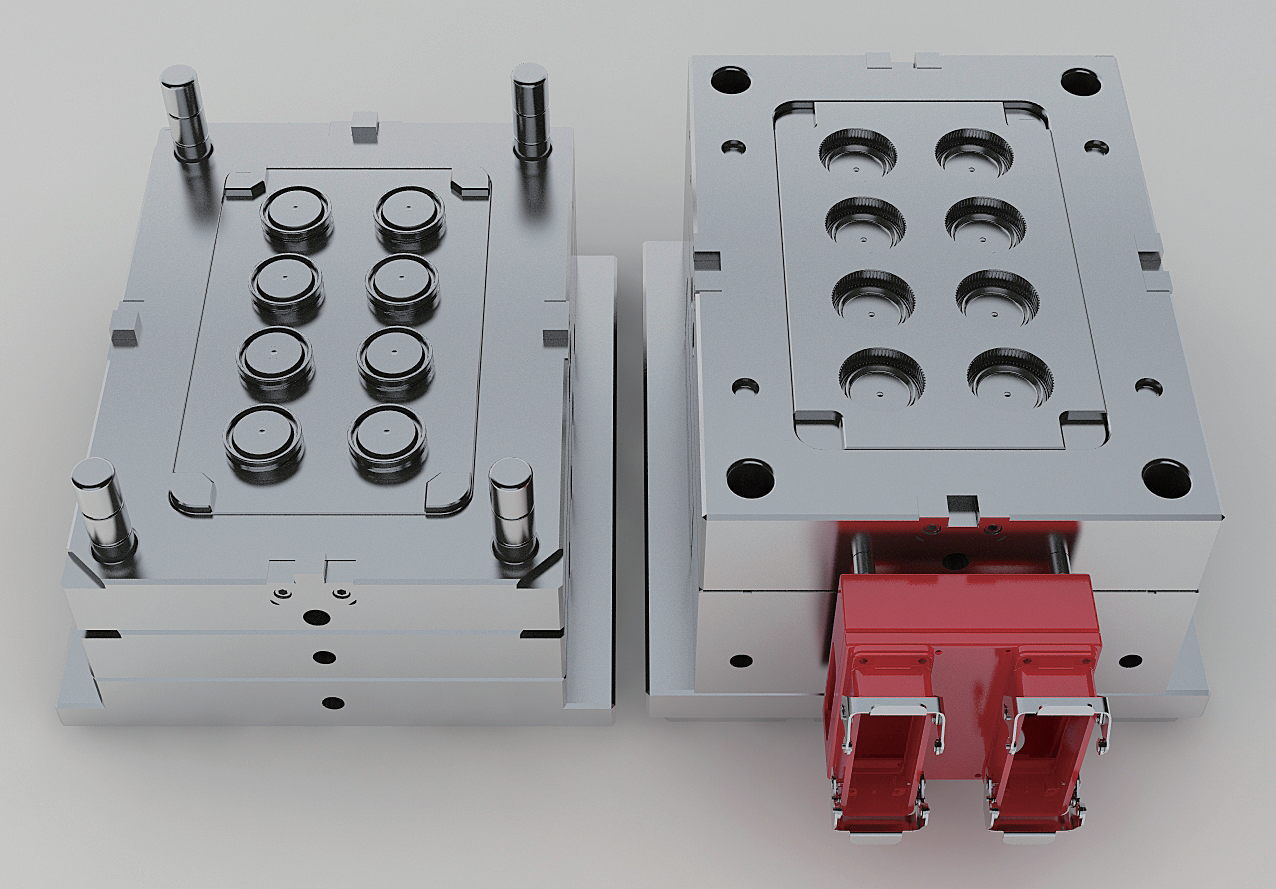

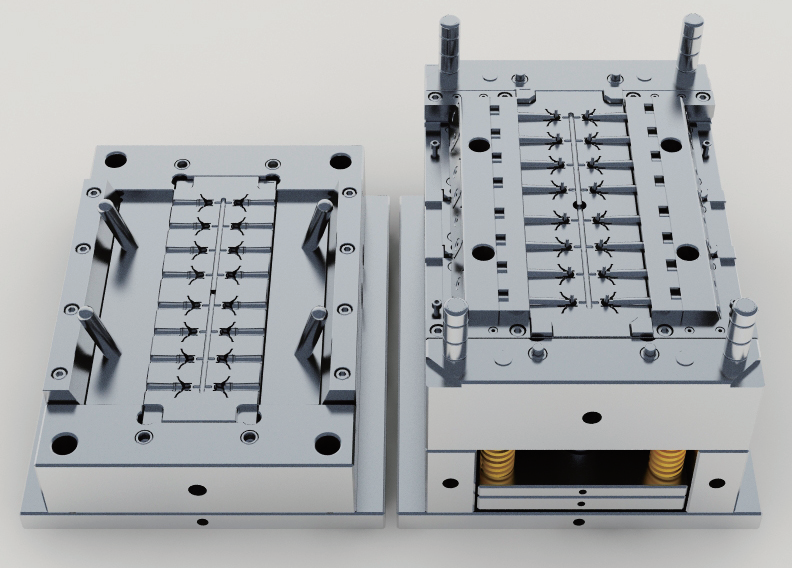

Benchtop injection molding represents a compact and efficient manufacturing solution designed for small-scale production and prototyping needs. This innovative technology brings industrial-grade injection molding capabilities to a desktop-sized format, making it accessible for small businesses, research facilities, and educational institutions. The system operates by melting plastic pellets and injecting the molten material into precisely engineered molds under controlled pressure and temperature conditions. With its sophisticated control systems, users can adjust parameters such as injection pressure, temperature, cooling time, and material flow rate to achieve optimal results. The machine's compact footprint typically measures less than 3 feet in any dimension, yet it maintains the capability to produce high-quality plastic parts with complex geometries. Modern benchtop injection molding machines often feature user-friendly digital interfaces, automated cycle operations, and precise temperature control zones. These systems can process a wide range of thermoplastic materials, including common polymers like ABS, PLA, PE, and PP, making them versatile tools for various applications, from product development to small-batch production runs. The technology bridges the gap between 3D printing and full-scale injection molding, offering a practical solution for producing functional plastic parts with production-grade materials.