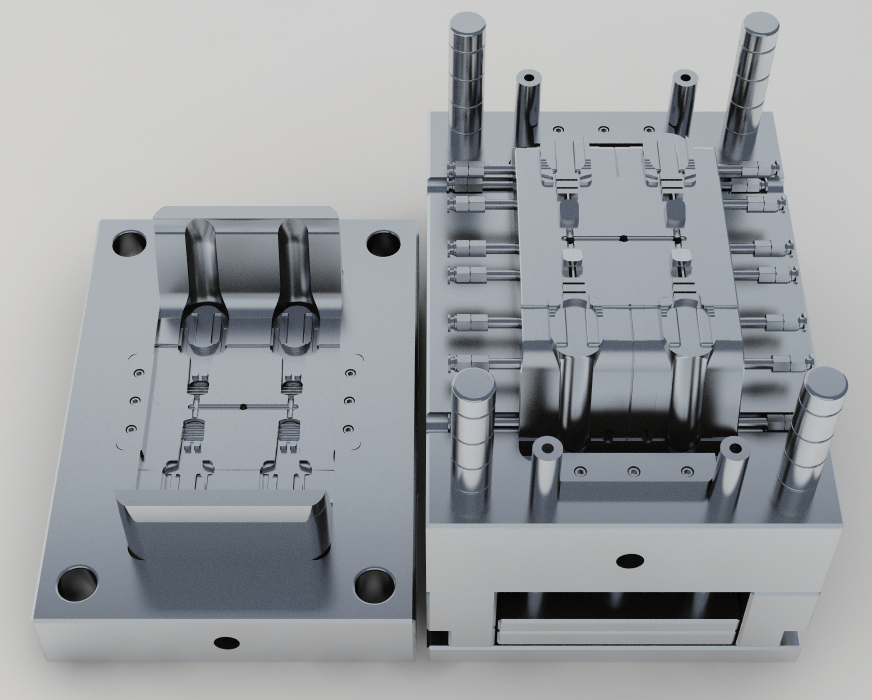

oem injection molding

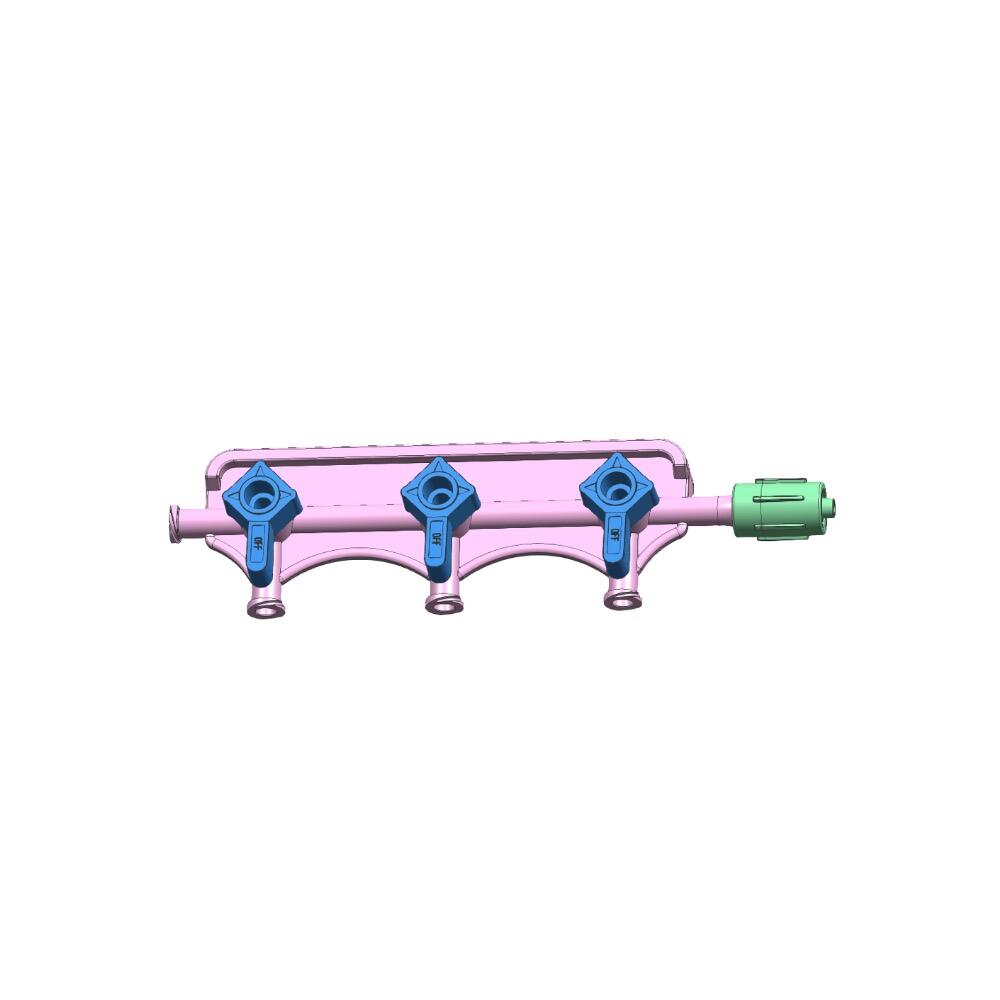

OEM injection molding represents a sophisticated manufacturing process that combines precision engineering with cost-effective production methods. This advanced manufacturing technique involves injecting molten materials, typically thermoplastics, into custom-designed molds to create specific components according to Original Equipment Manufacturer specifications. The process begins with detailed product design and mold creation, followed by material selection and optimization of injection parameters. Modern OEM injection molding facilities utilize computer-controlled systems to maintain precise temperature, pressure, and timing controls, ensuring consistent quality across large production runs. The technology accommodates a wide range of materials, from standard plastics to engineering-grade resins, allowing manufacturers to meet diverse product requirements. This versatility makes it ideal for producing complex geometries, intricate details, and components requiring tight tolerances. The process is particularly valuable in industries such as automotive, consumer electronics, medical devices, and household appliances, where high-volume production of precise components is essential. Advanced quality control measures, including real-time monitoring and automated inspection systems, ensure that each part meets exact specifications and maintains consistency throughout the production run.