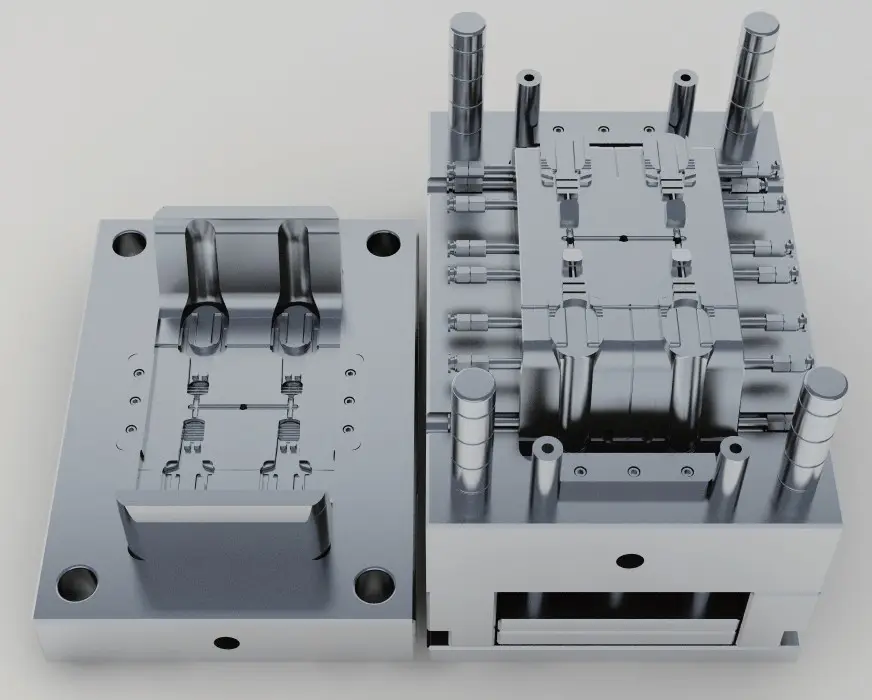

oem molding

OEM molding represents a sophisticated manufacturing process that enables businesses to create custom plastic components according to specific design requirements. This versatile production method combines precision engineering with cost effective manufacturing, allowing companies to produce high quality parts at scale. The process involves creating custom molds based on detailed specifications, which are then used to manufacture components through various molding techniques including injection molding, compression molding, or blow molding. Modern OEM molding incorporates advanced technologies such as computer aided design (CAD) and computer aided manufacturing (CAM) systems to ensure precise dimensional accuracy and consistent quality across production runs. The technology supports a wide range of materials, from standard thermoplastics to high performance engineering polymers, making it suitable for diverse applications across automotive, consumer electronics, medical devices, and industrial equipment sectors. Quality control measures are integrated throughout the production process, from initial design validation to final product inspection, ensuring that each component meets strict specifications and industry standards.