injection molding oem

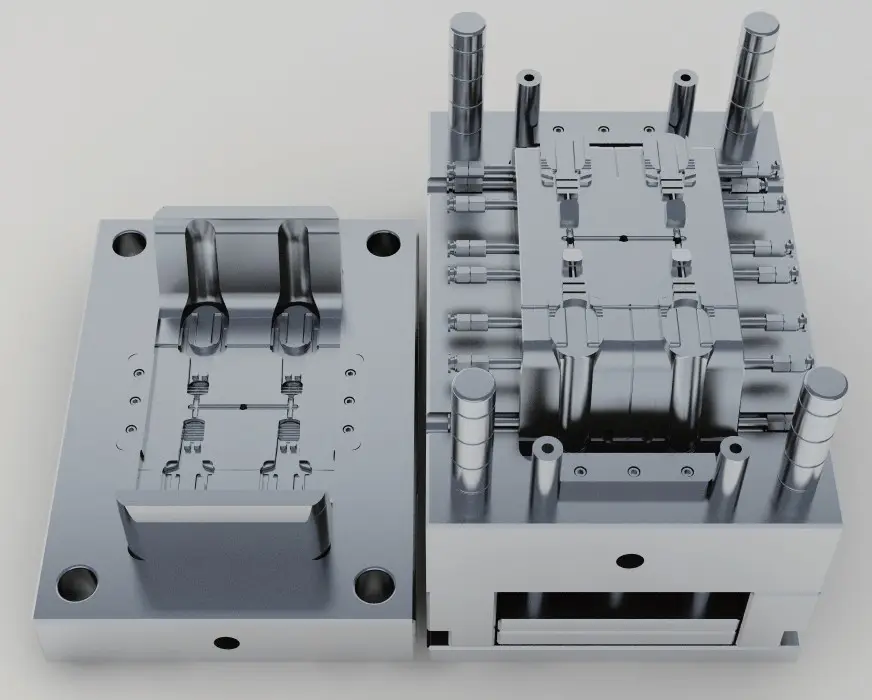

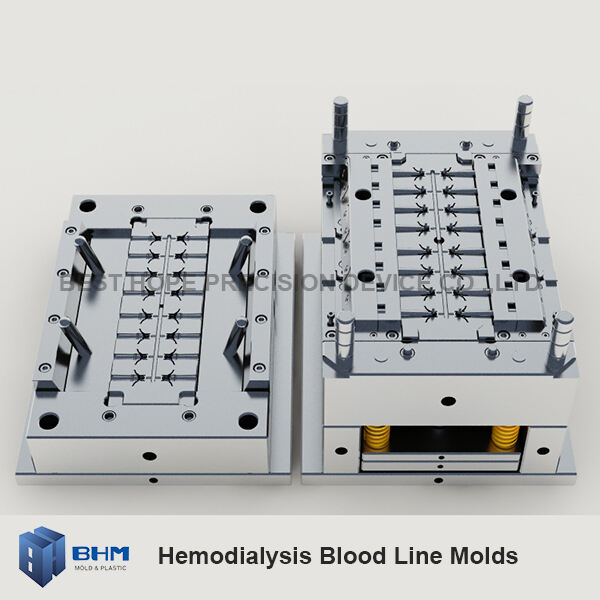

Injection molding OEM services represent a comprehensive manufacturing solution that combines precision engineering with cost-effective production methods. This specialized service encompasses the complete process of designing, manufacturing, and delivering custom plastic components through injection molding technology. The process begins with detailed product design and mold engineering, utilizing advanced CAD/CAM systems to ensure optimal part performance and manufacturability. Modern injection molding OEM facilities employ state-of-the-art machinery capable of producing parts with complex geometries, consistent quality, and tight tolerances. These facilities typically feature automated systems for material handling, quality control, and post-molding operations, ensuring high efficiency and reliability. The service extends beyond mere production to include material selection guidance, design optimization for manufacturing, prototype development, and quality assurance protocols. OEM providers maintain strict quality management systems, often certified to international standards like ISO 9001, and employ advanced inspection equipment to verify part specifications. This comprehensive approach enables the production of components ranging from simple consumer products to complex industrial parts, serving industries such as automotive, medical, electronics, and consumer goods.