plastic injection molding inc

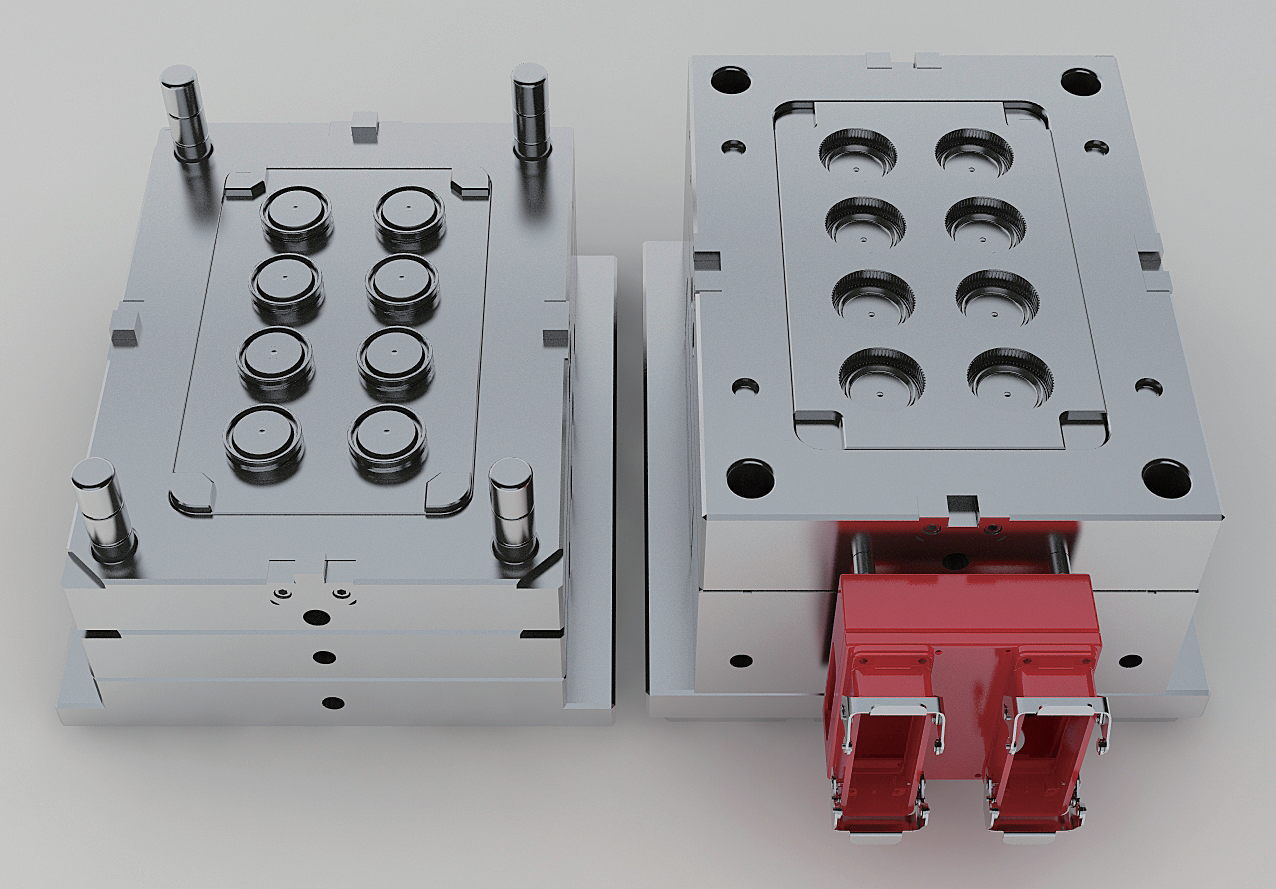

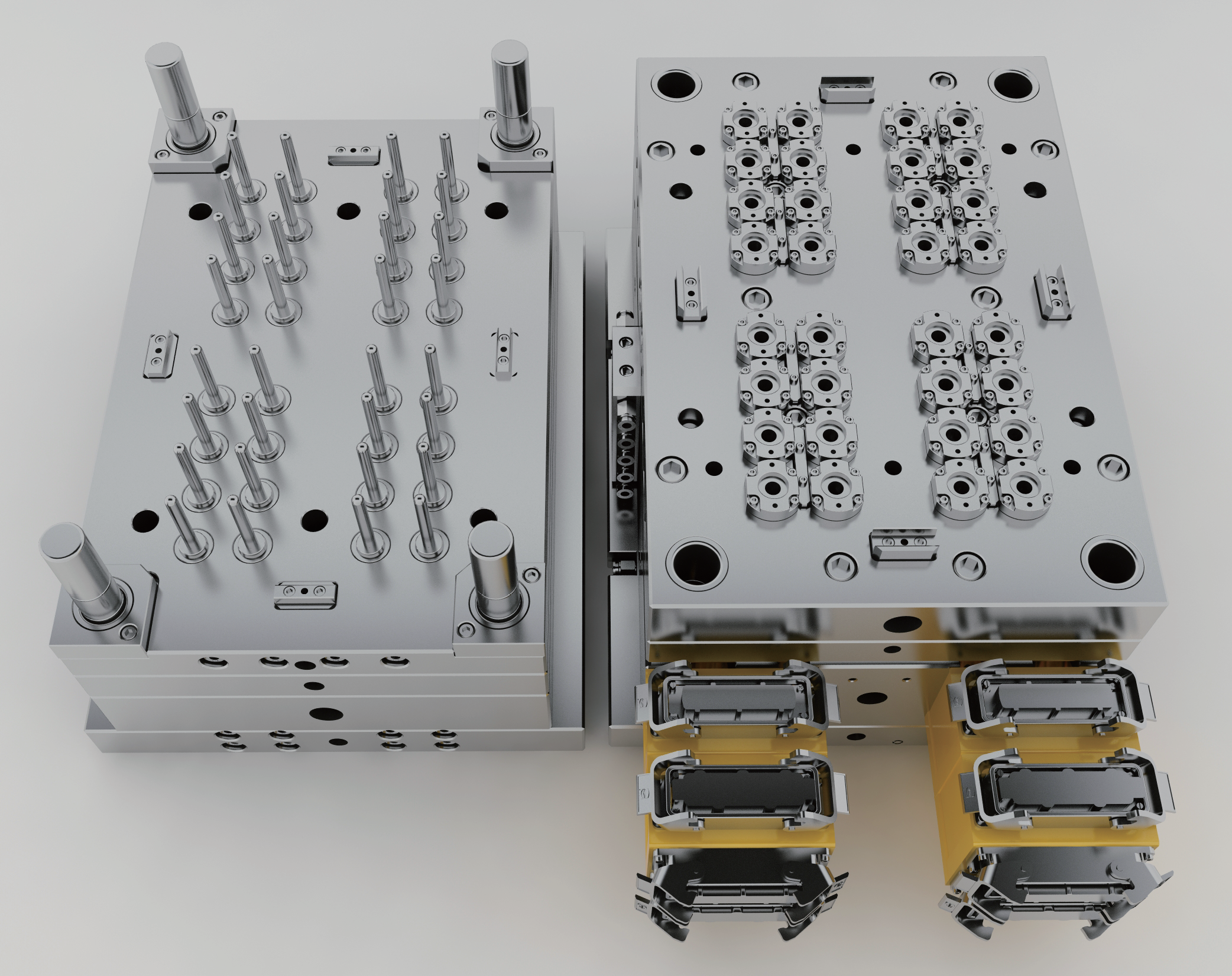

Plastic injection molding inc represents a cornerstone manufacturing process that revolutionizes the production of plastic components across various industries. This sophisticated technology involves injecting molten plastic material into precisely engineered molds under high pressure, creating complex parts with exceptional accuracy and consistency. The process begins with plastic pellets being melted and then forced into a carefully designed mold cavity, where it cools and solidifies into the desired shape. Modern plastic injection molding facilities incorporate advanced automation systems, quality control measures, and computer-aided design capabilities to ensure optimal production efficiency and product quality. The technology enables manufacturers to produce large volumes of identical parts with minimal waste, making it highly cost-effective for mass production. The versatility of this process allows for the creation of components ranging from simple consumer goods to complex medical devices and automotive parts. With the integration of smart manufacturing principles and Industry 4.0 technologies, plastic injection molding continues to evolve, offering improved precision, reduced cycle times, and enhanced material optimization.