plastic molded products

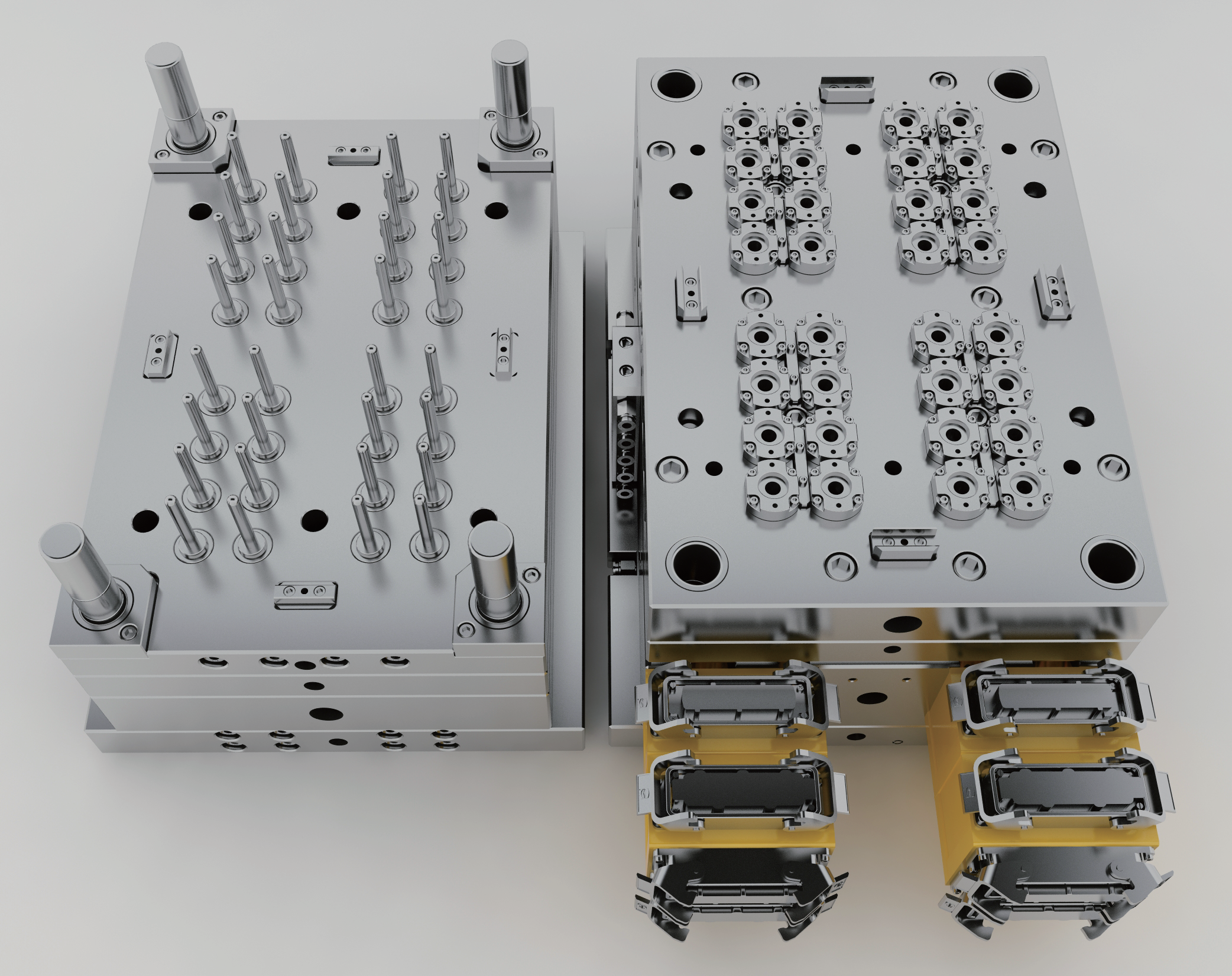

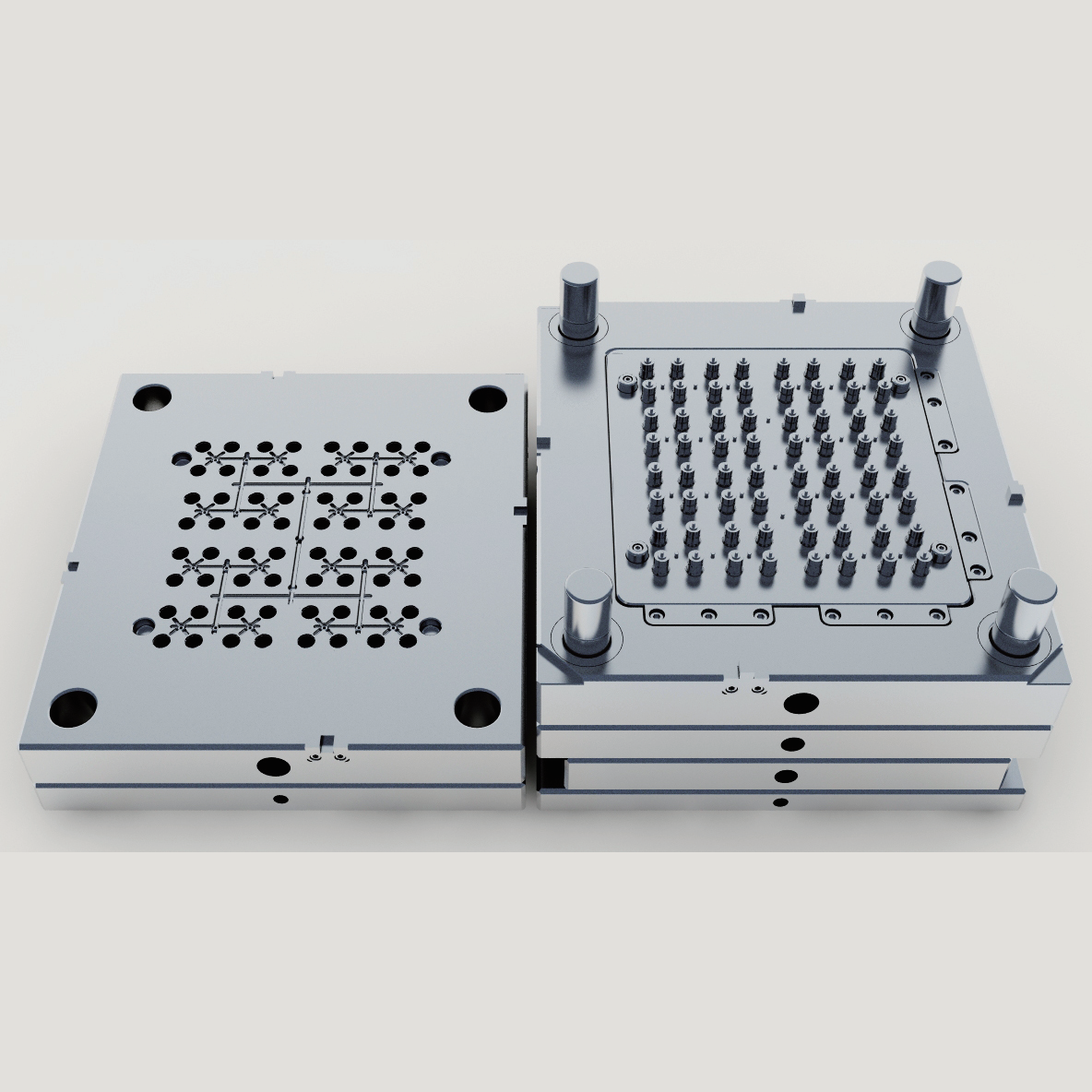

Plastic molded products represent a cornerstone of modern manufacturing, offering versatile solutions across numerous industries. These products are created through sophisticated injection molding processes, where molten plastic material is injected into precisely engineered molds under controlled pressure and temperature conditions. The resulting products exhibit exceptional consistency in quality, dimensional accuracy, and surface finish. The technology enables the production of complex geometries and intricate details that would be difficult or impossible to achieve through other manufacturing methods. From automotive components and consumer electronics housings to medical devices and household items, plastic molded products serve countless applications. The manufacturing process allows for the integration of various features such as threads, snap-fits, and living hinges directly into the molded parts, eliminating the need for secondary operations. Modern plastic molding techniques also accommodate a wide range of materials, including engineering-grade polymers, thermoplastics, and specialty compounds, each selected to meet specific performance requirements such as heat resistance, chemical compatibility, or mechanical strength. The scalability of production, from prototype runs to high-volume manufacturing, makes plastic molding a cost-effective solution for businesses of all sizes.