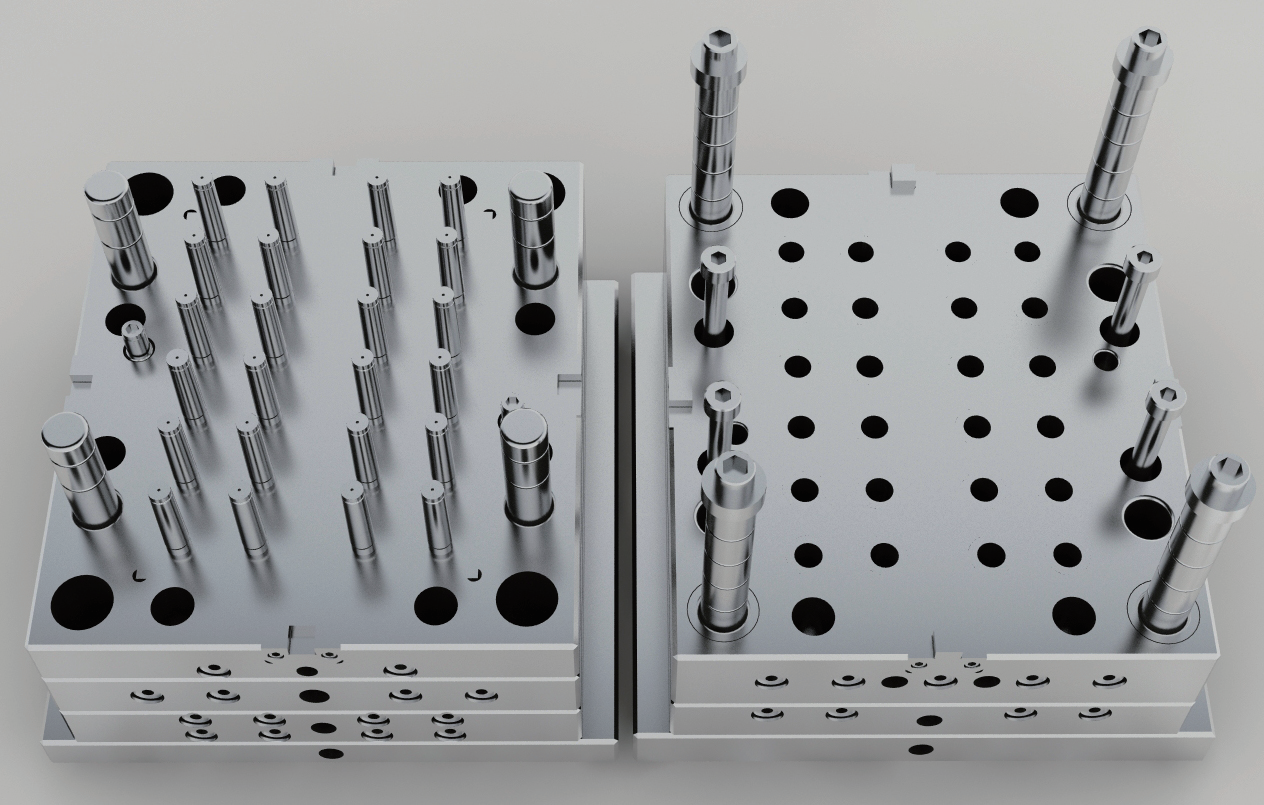

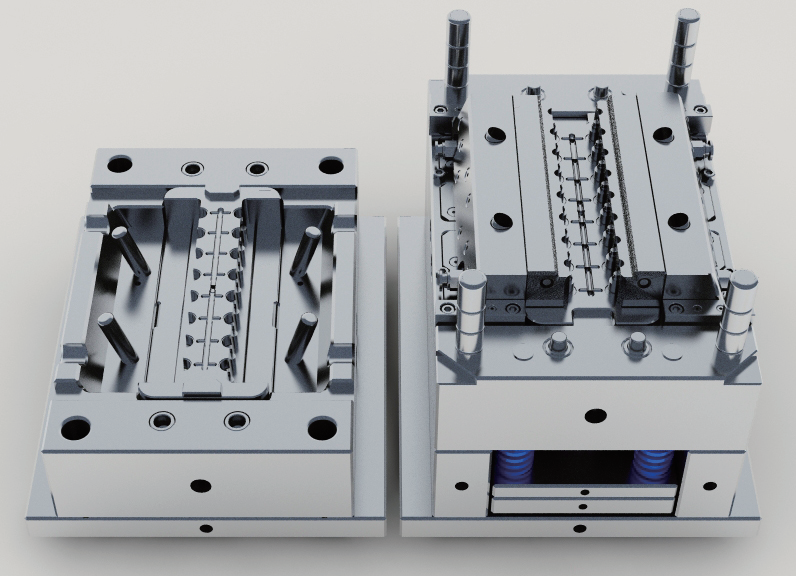

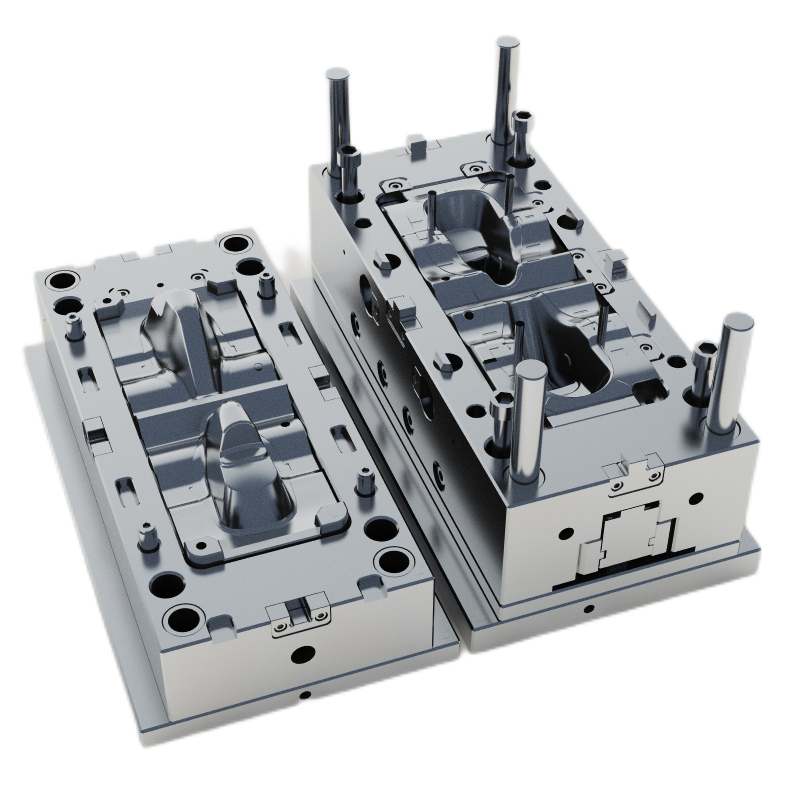

family mold injection molding

Family mold injection molding represents an advanced manufacturing technique that enables the simultaneous production of multiple different parts within a single mold cavity. This innovative approach combines efficiency with versatility by allowing manufacturers to produce various components in one production cycle. The technology utilizes a sophisticated mold design that incorporates multiple cavities, each specifically engineered to create different parts while maintaining consistent quality across all components. The process begins with the injection of molten plastic material into the various cavities, where it cools and solidifies to form the desired parts. Family molds are particularly valuable in scenarios where related parts need to be produced together, such as components that will be assembled into a final product. The technology incorporates advanced cooling systems and precise temperature control mechanisms to ensure uniform cooling across different cavity sizes and shapes. This manufacturing method significantly reduces production time, tooling costs, and material waste while ensuring consistent quality across all parts produced. It's widely used in industries ranging from automotive and consumer electronics to medical devices and household products, where multiple related components are required for assembly.