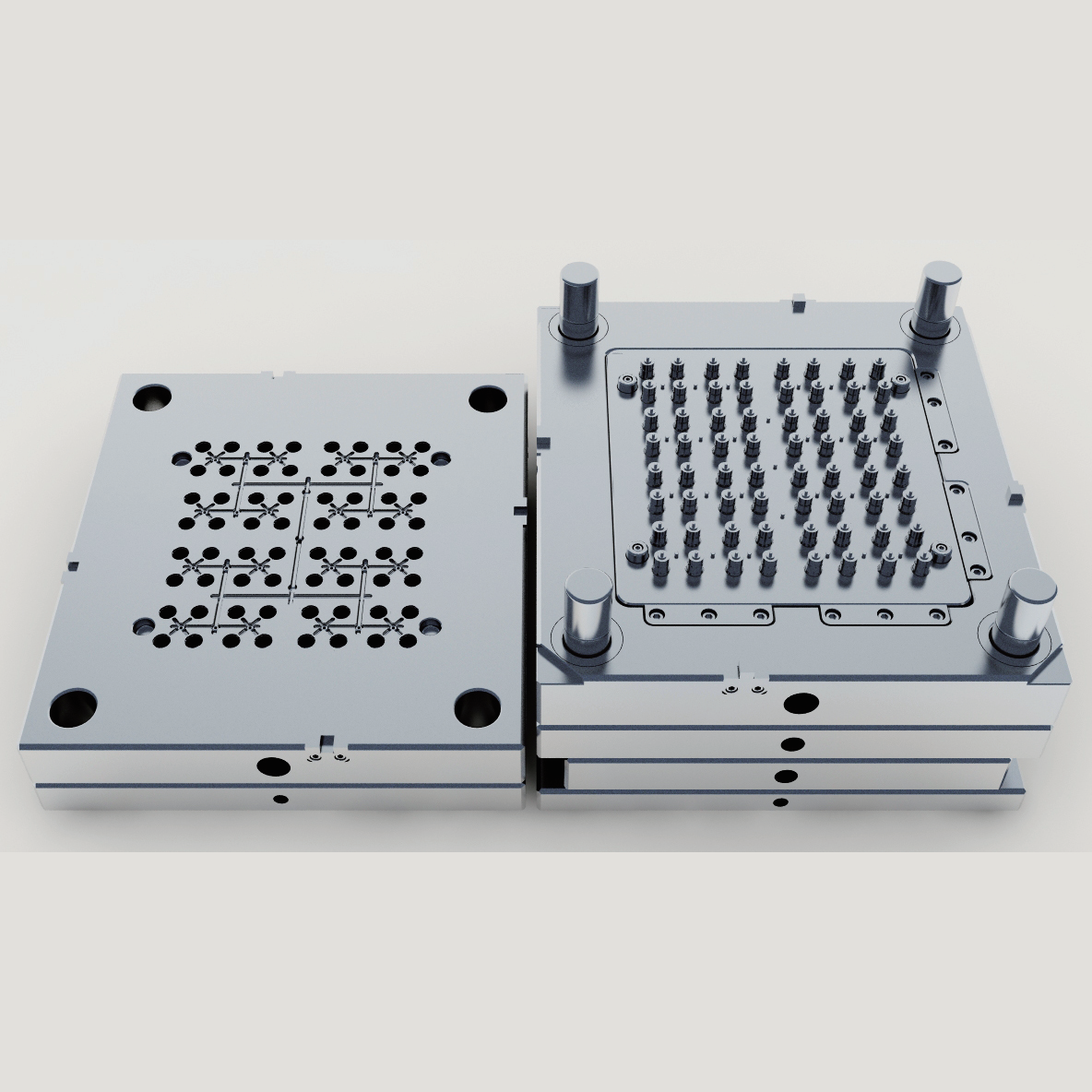

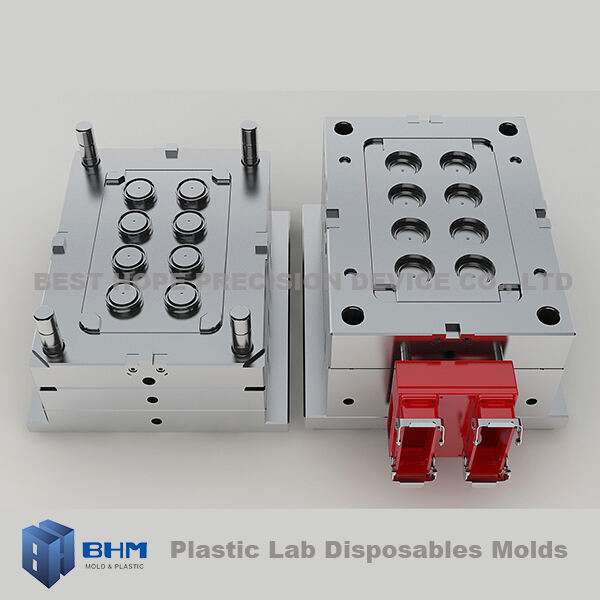

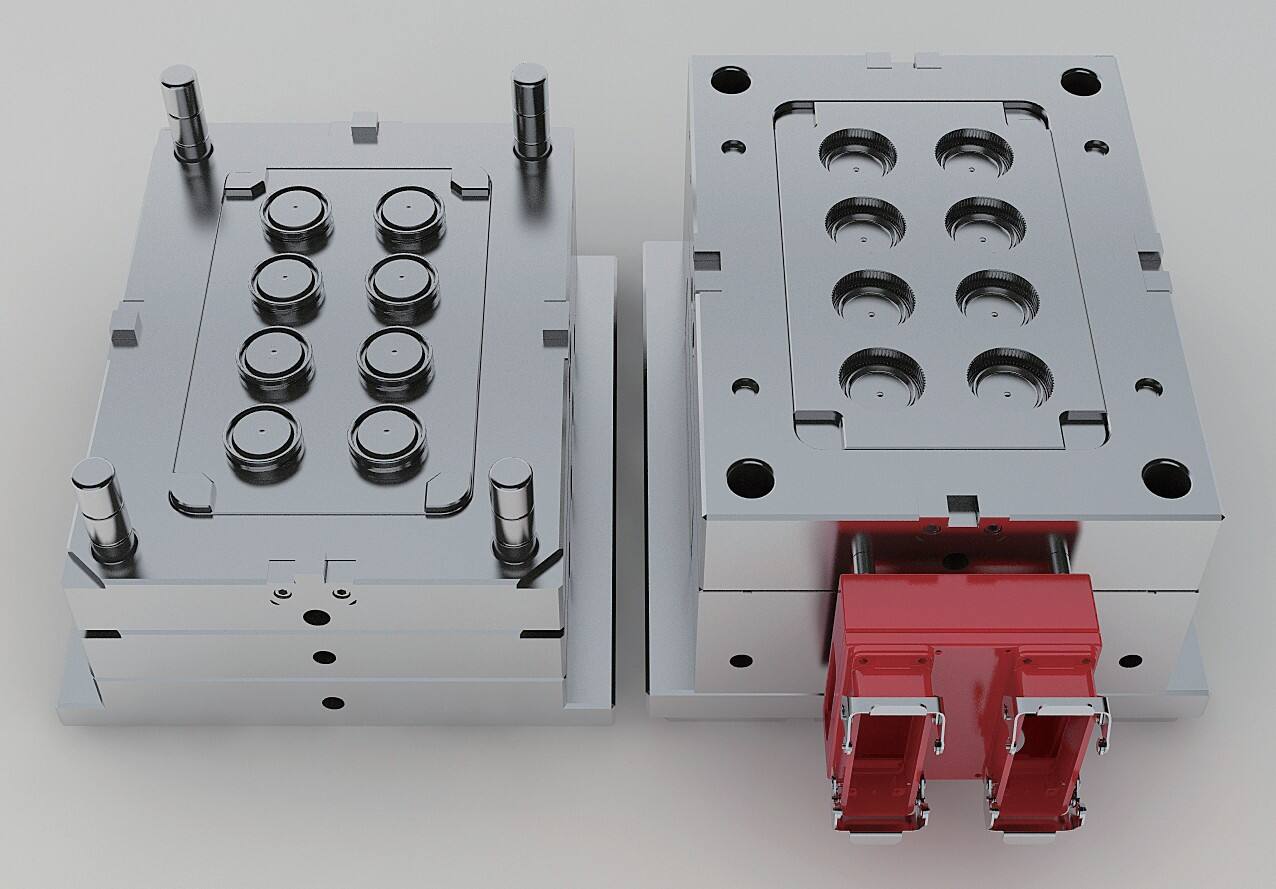

complex injection molding

Complex injection molding represents a sophisticated manufacturing process that enables the production of intricate plastic components with exceptional precision and efficiency. This advanced technology combines traditional injection molding principles with innovative features to create parts with complex geometries, multiple materials, or internal structures that would be impossible to achieve through conventional molding methods. The process involves carefully engineered mold designs, precise temperature control, and specialized injection sequences to ensure optimal material flow and part formation. By utilizing advanced computer-controlled systems, complex injection molding can manage multiple injection points, various material combinations, and precise timing sequences to produce components with specific mechanical properties, aesthetic features, and functional requirements. The technology excels in creating parts with undercuts, internal cavities, multiple colors, or different material hardnesses within a single component. Industries such as automotive, medical devices, consumer electronics, and aerospace rely heavily on complex injection molding for producing sophisticated components that meet strict quality and performance standards. This manufacturing method has revolutionized product design possibilities by allowing engineers to create increasingly complex parts while maintaining cost-effectiveness in high-volume production scenarios.