small batch injection molding

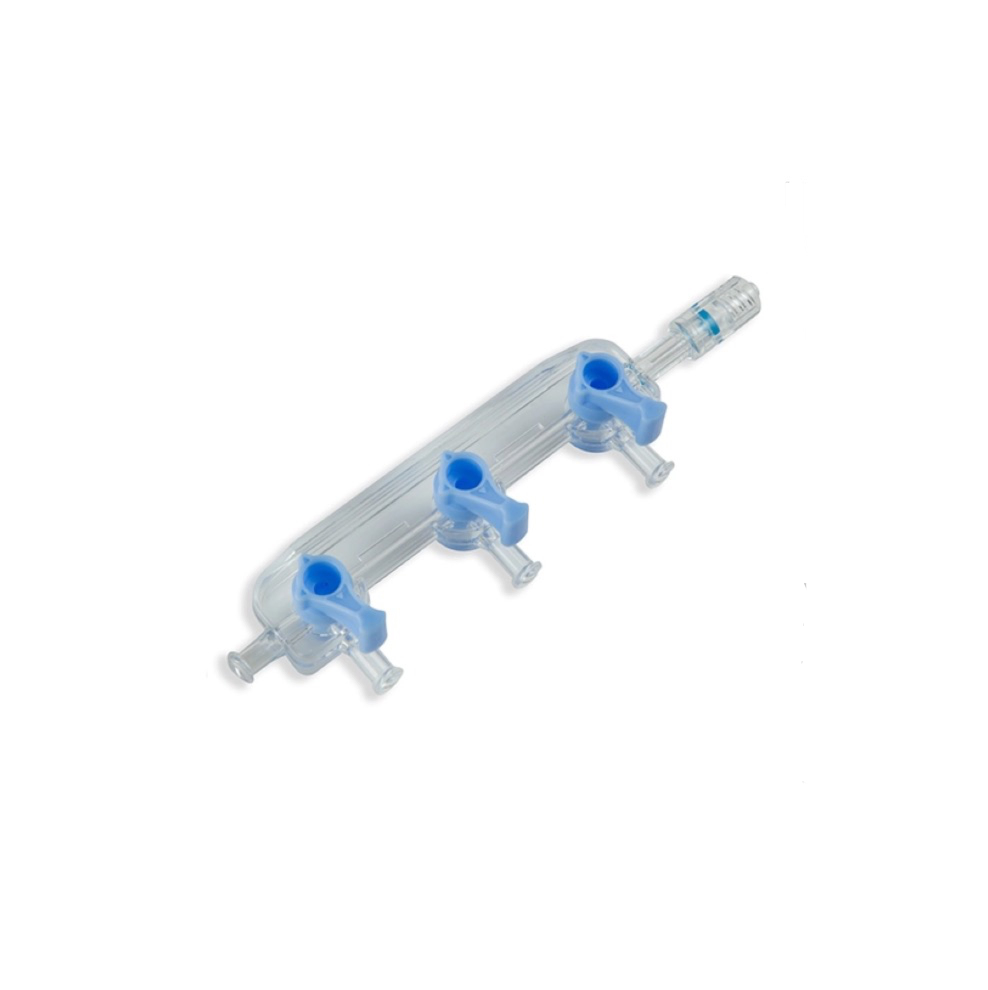

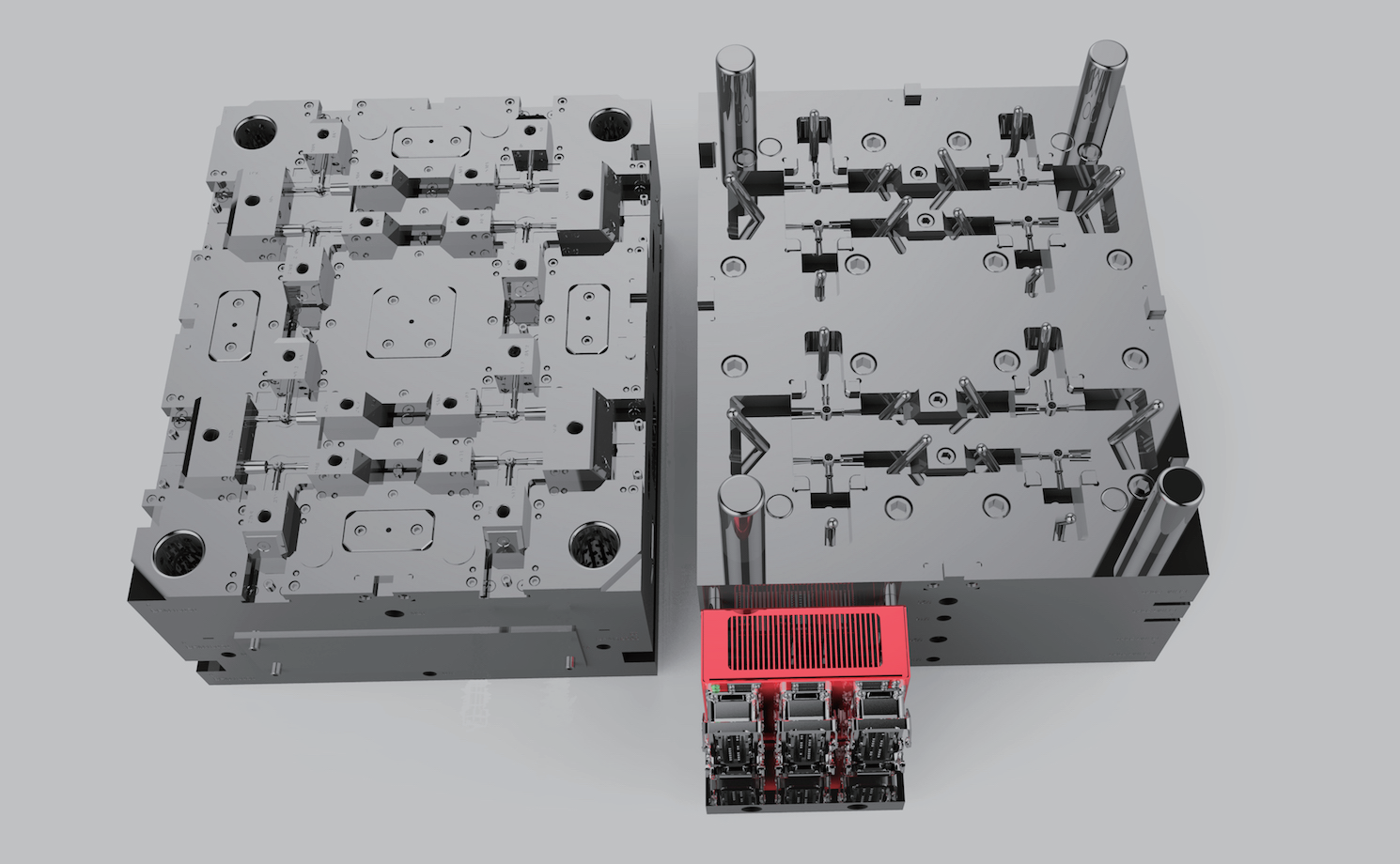

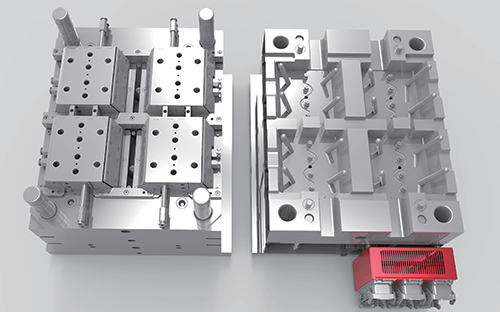

Small batch injection molding represents a cutting-edge manufacturing process that enables the production of plastic components in limited quantities while maintaining high quality and cost-effectiveness. This innovative approach bridges the gap between prototype development and mass production, offering manufacturers flexibility in production volumes. The process utilizes specialized equipment designed to handle smaller production runs efficiently, typically ranging from 50 to 10,000 pieces. The technology incorporates advanced digital controls, automated material handling systems, and precise temperature regulation to ensure consistent part quality. What sets small batch injection molding apart is its ability to utilize both standard and engineering-grade thermoplastics, allowing for a wide range of material options to meet specific application requirements. The process employs sophisticated mold designs that can be quickly changed or modified, reducing setup times and enabling rapid transitions between different products. This manufacturing method finds extensive applications across various industries, including medical devices, consumer electronics, automotive parts, and specialized industrial components. The technology's precision and repeatability make it particularly valuable for producing complex geometries and parts with tight tolerances, while its scalability allows manufacturers to adjust production volumes based on demand fluctuations.