tpu injection molding

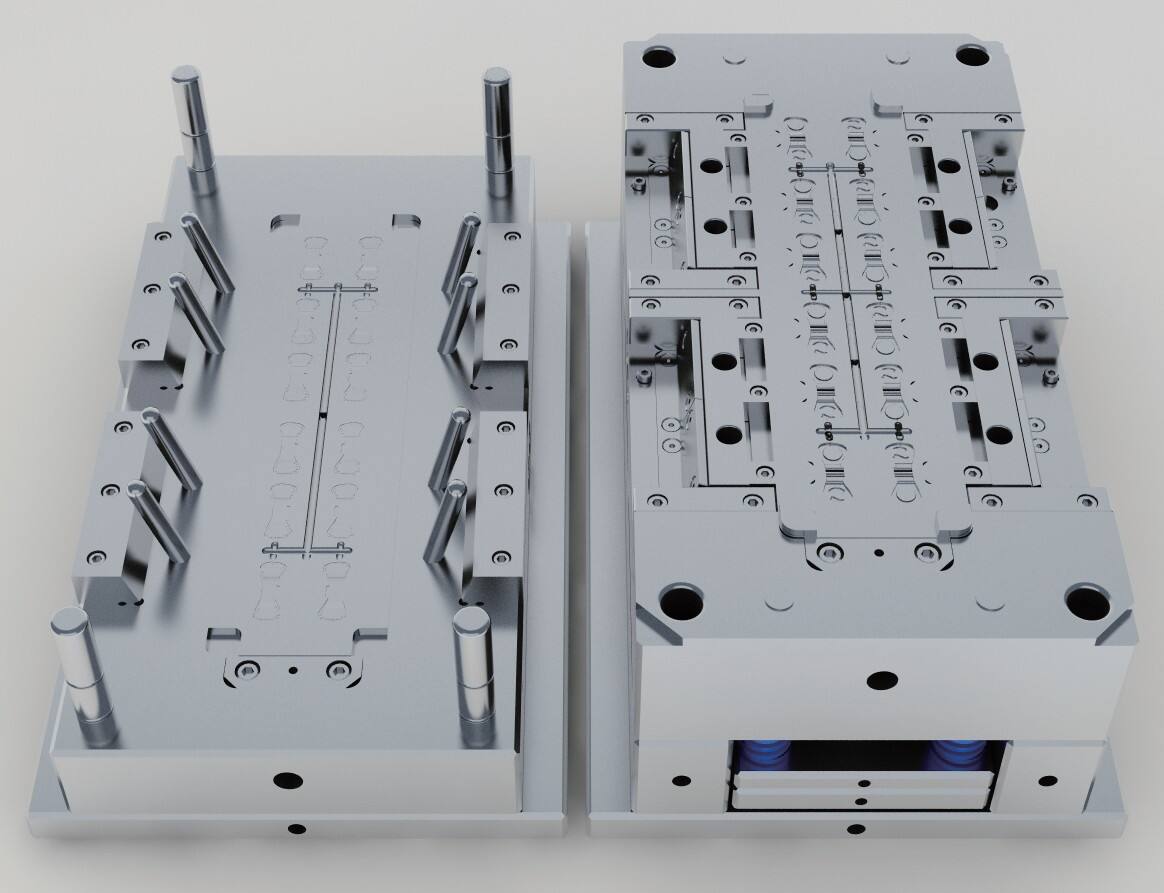

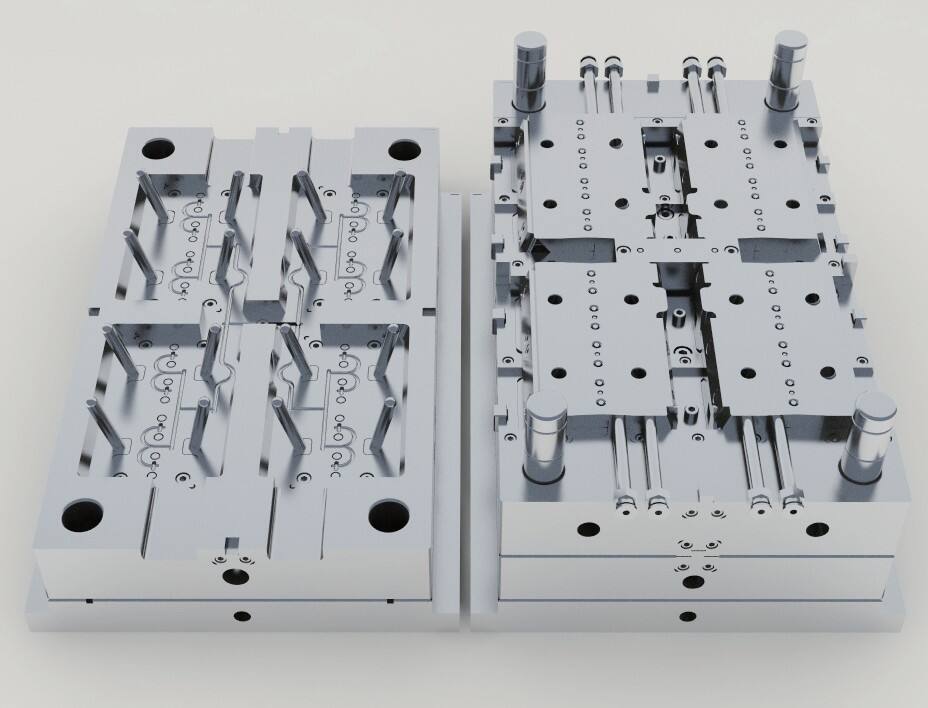

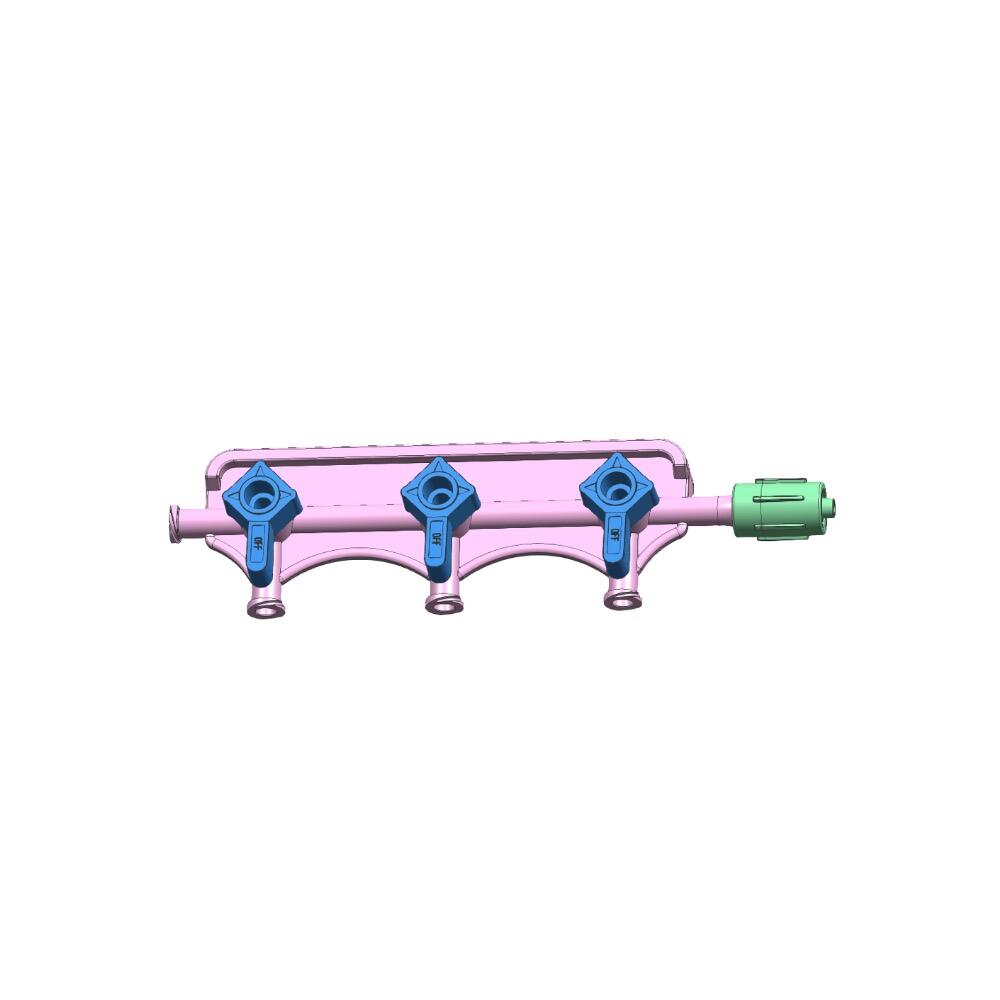

TPU injection molding is a sophisticated manufacturing process that combines the versatility of thermoplastic polyurethane with precision injection molding techniques. This advanced manufacturing method involves heating TPU pellets until they reach a molten state, then injecting the material into carefully designed molds under high pressure. The process enables the production of complex, durable parts with exceptional flexibility and wear resistance. The technology allows for precise control over material flow, temperature, and pressure parameters, resulting in consistent, high-quality products. TPU injection molding is particularly notable for its ability to create parts with varying hardness levels within the same component, known as multi-durometer molding. The process accommodates both small and large production runs, making it suitable for various industries including automotive, consumer electronics, medical devices, and sporting goods. The automated nature of the process ensures high repeatability and minimal waste, while the material properties of TPU provide excellent resistance to oils, chemicals, and abrasion. Modern TPU injection molding systems incorporate advanced features such as computer-controlled processing parameters, real-time monitoring, and quality control systems to maintain product consistency and reduce cycle times.