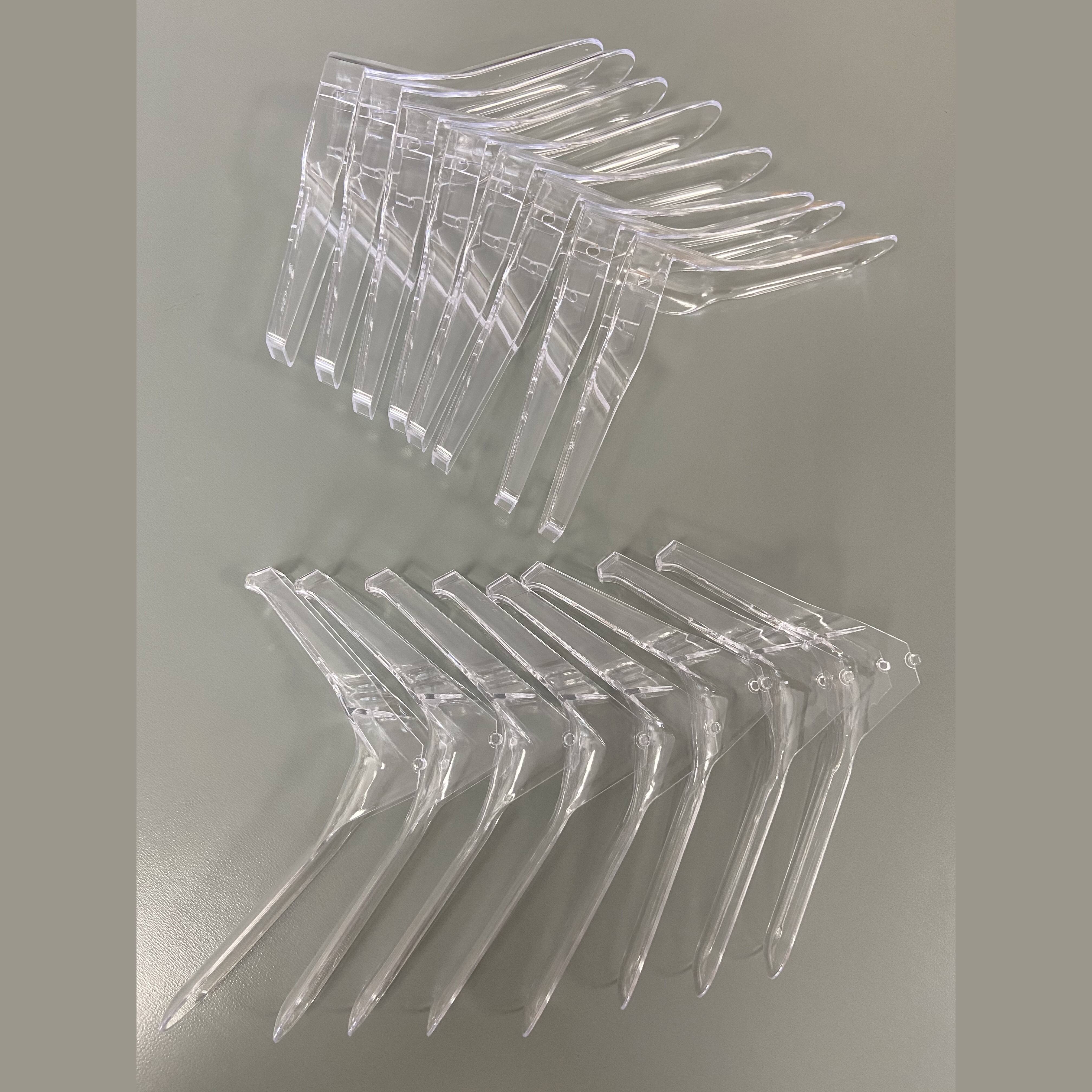

thin wall injection molding

Thin wall injection molding is a sophisticated manufacturing process designed to produce lightweight, highly detailed plastic components with wall thicknesses typically ranging from 0.5mm to 2.0mm. This advanced technique utilizes specialized equipment and precise process control to inject molten plastic material into thin cavity molds at high speeds and pressures. The process requires careful consideration of material selection, mold design, and processing parameters to achieve optimal results. Essential to modern manufacturing, this technology enables the production of complex geometries while maintaining structural integrity and dimensional accuracy. The process excels in creating parts that combine durability with minimal material usage, making it particularly valuable in industries where weight reduction is crucial. Key technological features include rapid injection speeds, high pressure capabilities, and advanced cooling systems that ensure proper material flow and prevent defects. Common applications span across various sectors, including consumer electronics, automotive components, medical devices, and packaging solutions. The technology's ability to produce thin-walled parts with excellent surface finish and consistent quality has made it indispensable in modern manufacturing, particularly for high-volume production runs where efficiency and precision are paramount.