custom injection molding services

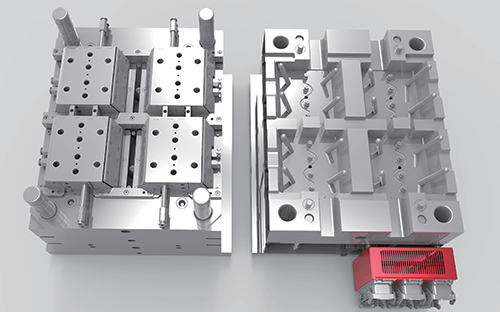

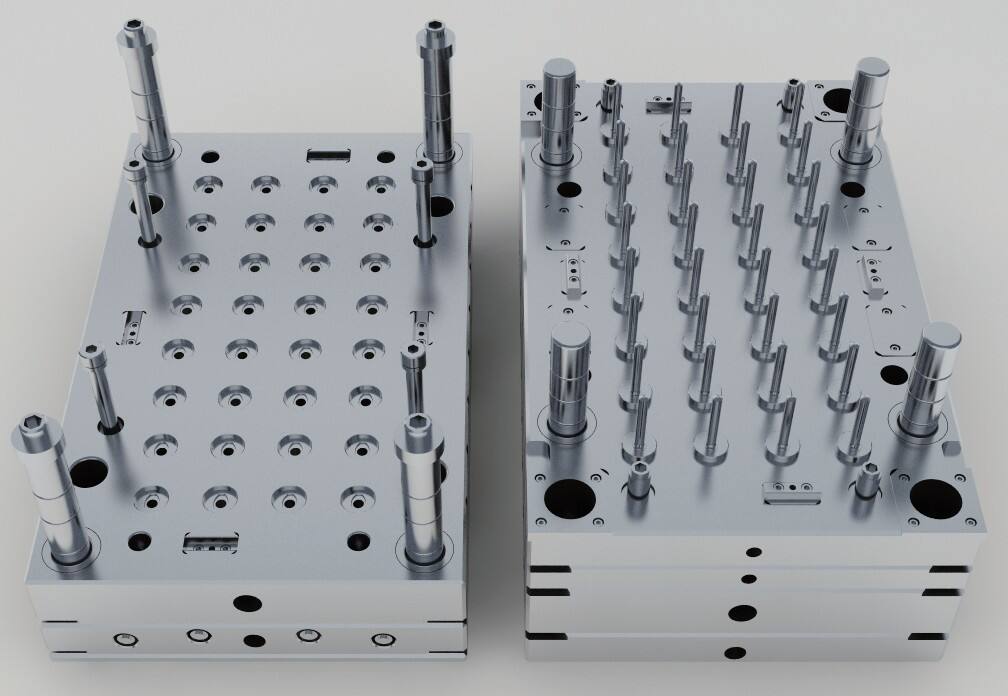

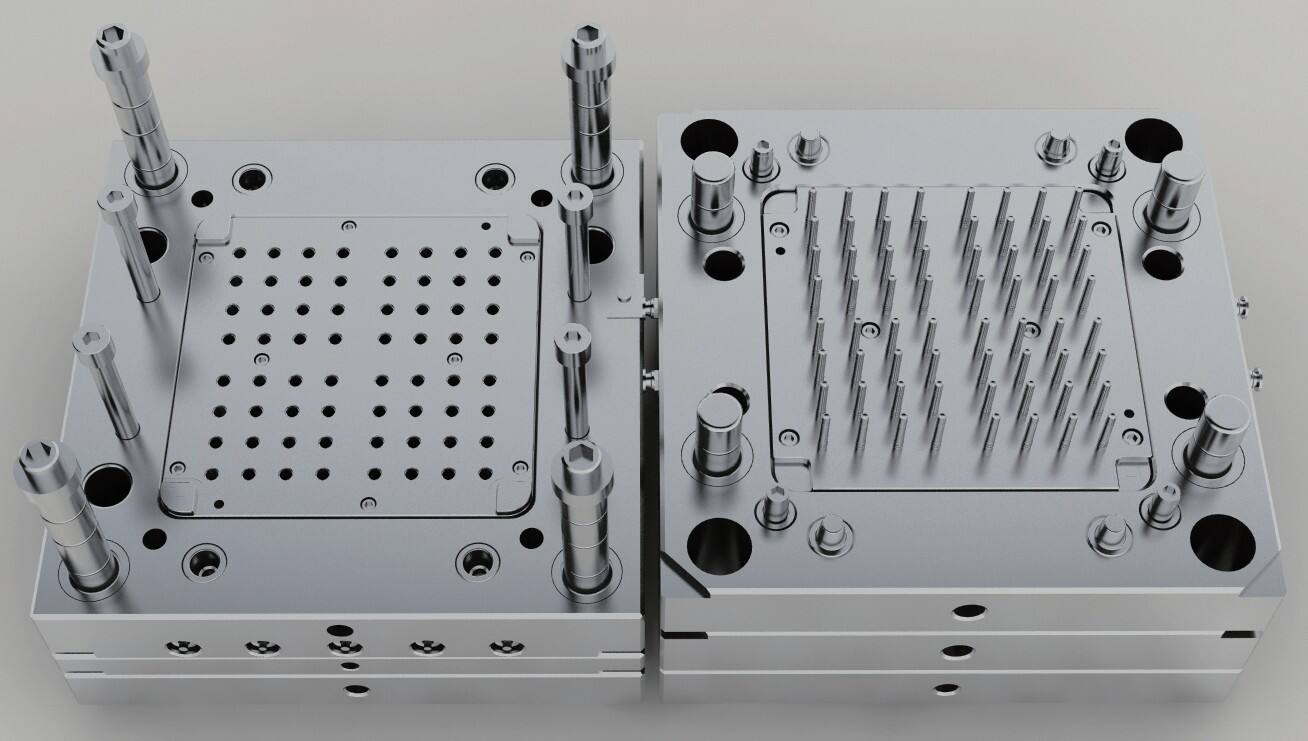

Custom injection molding services represent a sophisticated manufacturing process that enables the production of high-quality plastic parts with precise specifications and consistent quality. This advanced manufacturing method involves injecting molten plastic material into custom-designed molds under high pressure, creating complex components that meet exact requirements. The process begins with detailed design consultation, where engineering teams work closely with clients to optimize part designs for manufacturability. State-of-the-art equipment, including precision injection molding machines with advanced control systems, ensures tight tolerances and exceptional part consistency. The service encompasses comprehensive material selection guidance, helping clients choose from a wide range of engineering-grade resins that best suit their specific application requirements. Modern facilities utilize automated systems and quality control measures throughout the production cycle, from material handling to final inspection. The process accommodates various part sizes, shapes, and complexities, making it suitable for industries ranging from medical devices to automotive components. Advanced tooling capabilities allow for intricate details, multiple cavities, and specialized surface finishes, while automated assembly and secondary operations streamline production efficiency.