polymer injection molding

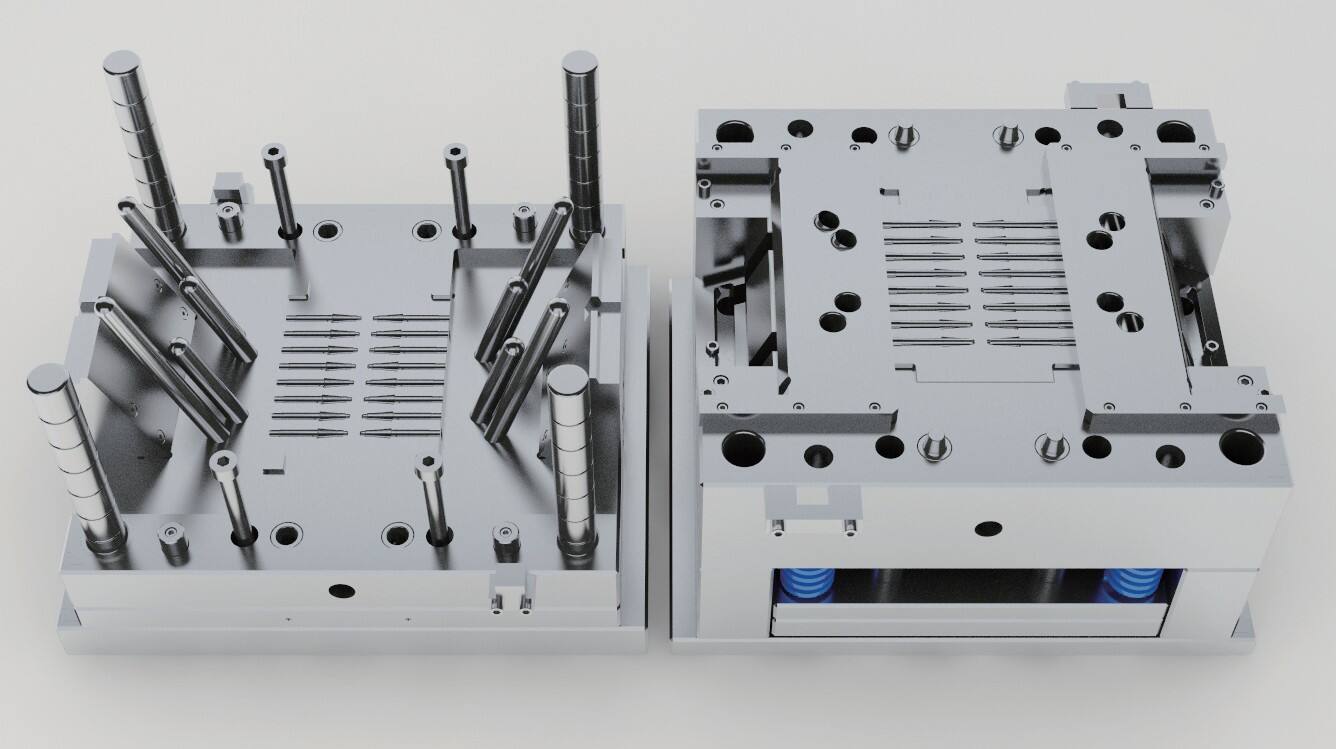

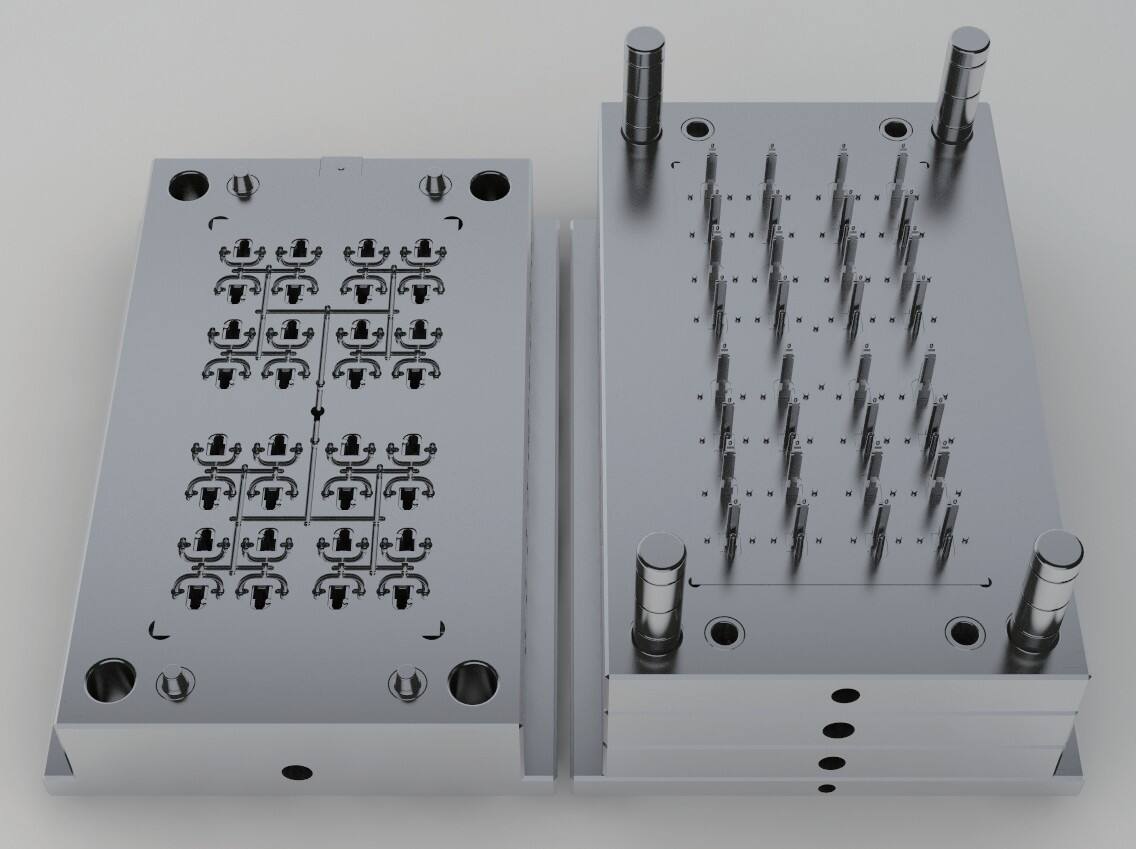

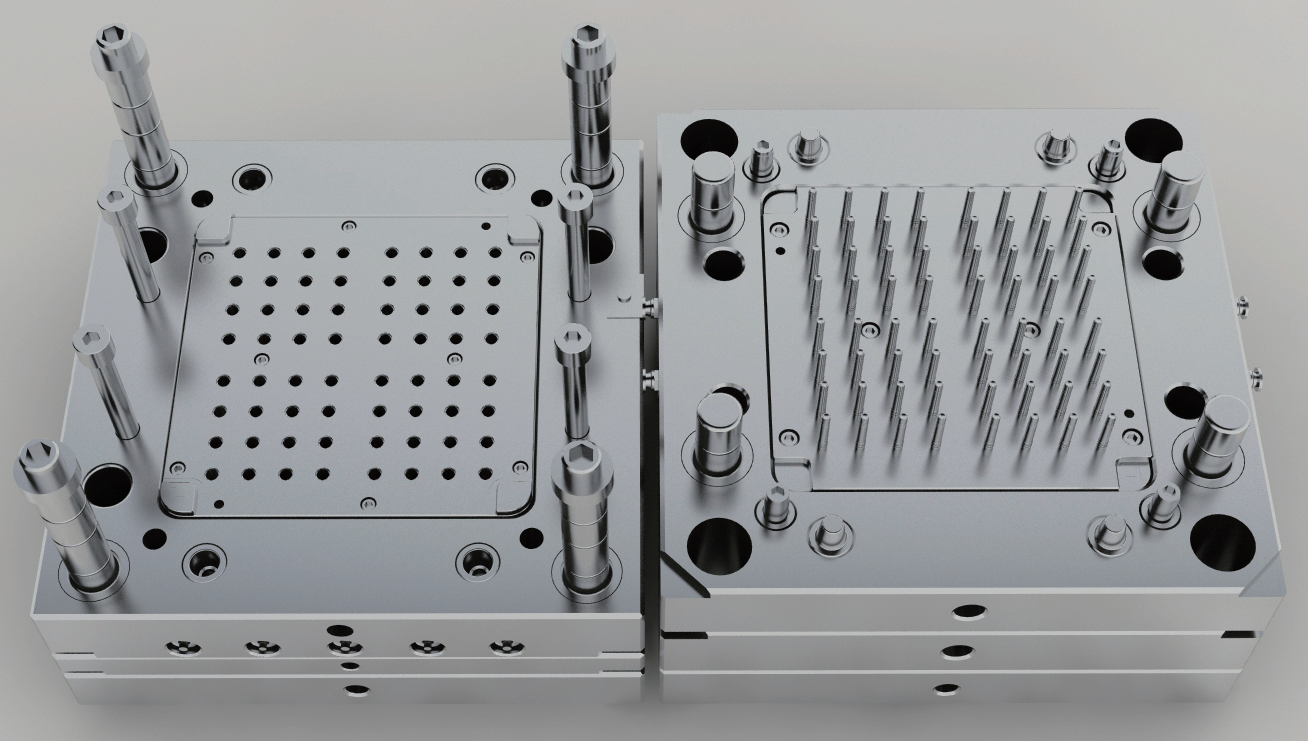

Polymer injection molding is a sophisticated manufacturing process that revolutionizes the production of plastic parts and components. This versatile technology involves heating polymer materials until they reach a molten state, then injecting them under high pressure into carefully designed molds. The process allows for the creation of complex geometries and intricate details that would be impossible or cost-prohibitive to achieve through other manufacturing methods. The technology employs advanced computer-controlled systems to maintain precise temperature control, injection pressure, and cooling rates, ensuring consistent quality across production runs. Modern injection molding machines can handle a wide range of thermoplastic and thermosetting polymers, enabling manufacturers to select the ideal material for specific applications. The process is highly automated, making it suitable for both small-batch production and high-volume manufacturing scenarios. Applications span numerous industries, including automotive parts, consumer electronics, medical devices, packaging, and household products. The ability to integrate different materials, colors, and textures in a single molding cycle has made this technology indispensable in modern manufacturing.