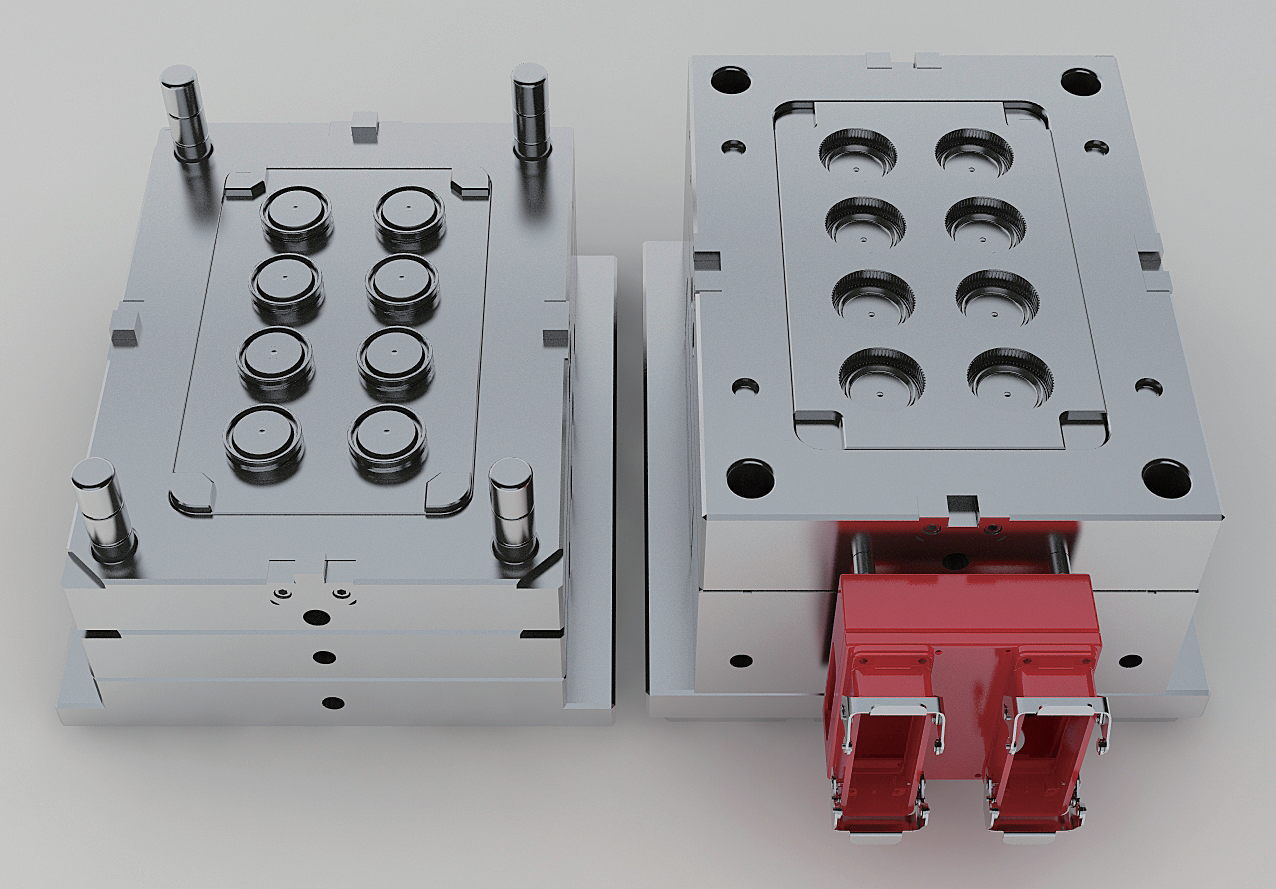

precision injection molding inc

Precision injection molding inc represents a cutting-edge manufacturing process that combines advanced technology with meticulous attention to detail to produce high-quality plastic components. This sophisticated manufacturing method employs state-of-the-art machinery and computer-controlled systems to inject molten material into precisely engineered molds under carefully regulated conditions. The company specializes in creating complex, highly detailed parts with exceptional accuracy, maintaining tolerances as tight as +/- 0.001 inches. The process utilizes advanced materials, including engineering-grade thermoplastics, and features automated quality control systems that ensure consistency across production runs. The facility houses multiple injection molding machines with varying tonnage capabilities, allowing for the production of components ranging from microscopic medical devices to larger automotive parts. The company's expertise extends to multi-material molding, insert molding, and overmolding technologies, providing versatile solutions for diverse industry applications. The manufacturing setup includes clean room facilities for medical and electronics production, automated assembly systems, and comprehensive testing equipment for quality assurance.