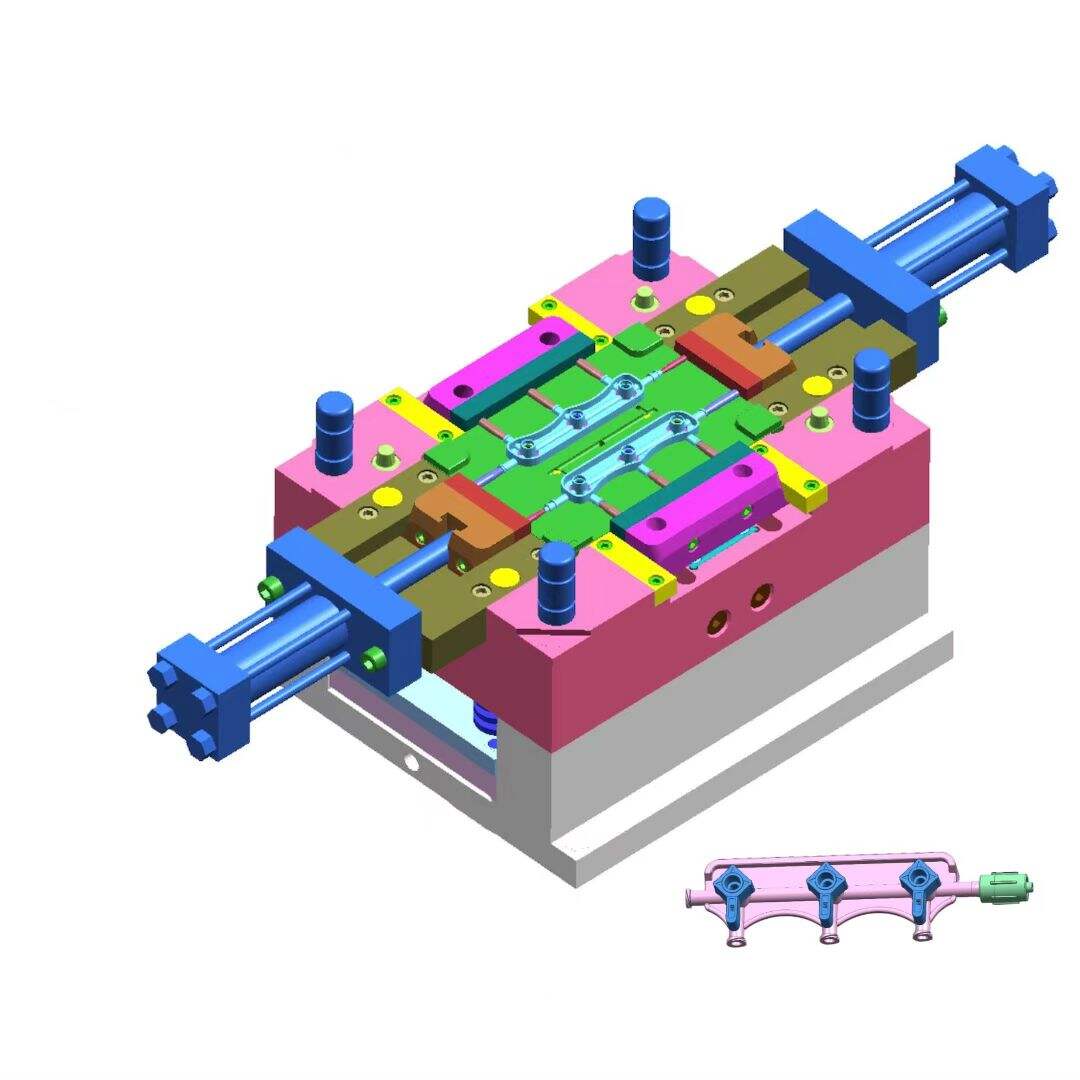

injection molding mold

An injection molding mold is a precision-engineered tool that serves as the cornerstone of plastic manufacturing processes. This sophisticated piece of equipment consists of two main components: the cavity and the core, which work together to create complex plastic parts with exceptional accuracy. The mold functions by receiving molten plastic material injected under high pressure, which then takes the shape of the carefully designed internal cavities. The technological features include advanced cooling channels that regulate temperature distribution, precisely calculated gates and runners that control material flow, and ejector systems that ensure smooth part removal. Modern injection molds often incorporate hot runner systems, which maintain plastic in a molten state between shots, reducing waste and improving efficiency. These molds can be designed with multiple cavities to produce several identical parts simultaneously, significantly increasing production output. The applications span across numerous industries, from automotive components and consumer electronics to medical devices and household products. The versatility of injection molding molds allows for the production of parts ranging from simple geometric shapes to highly complex components with intricate features, making them indispensable in modern manufacturing.