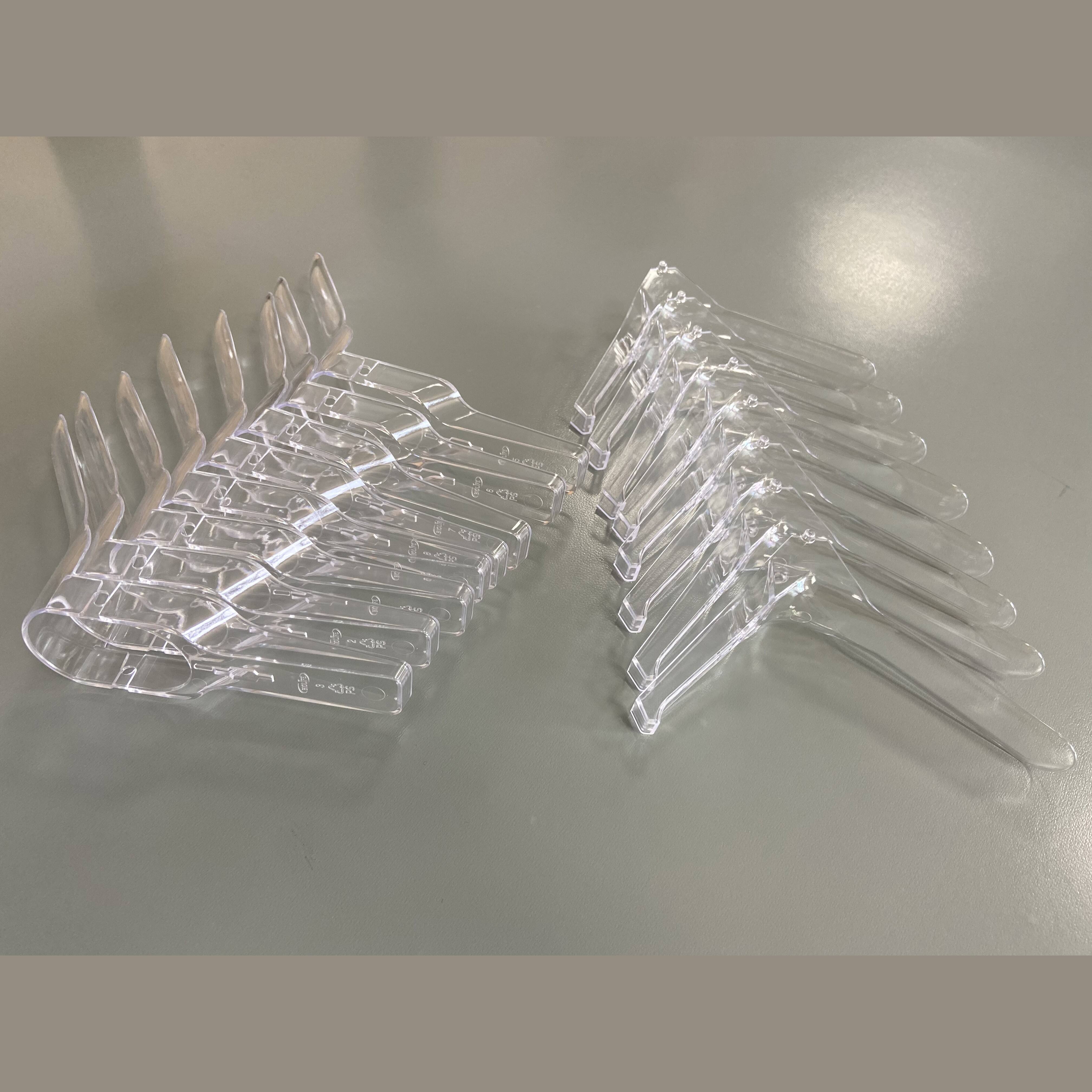

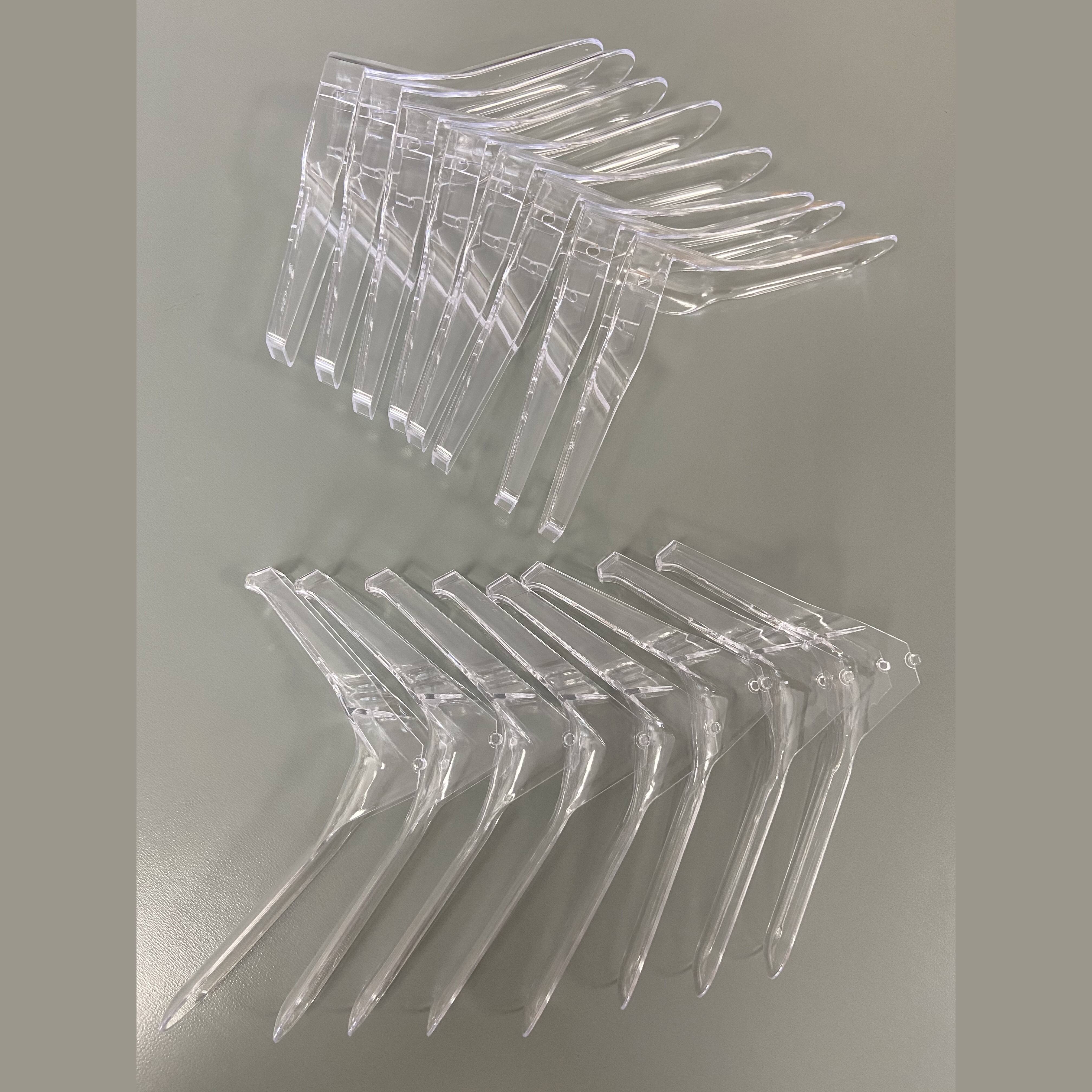

vertical injection molding

Vertical injection molding represents a specialized manufacturing process that distinguishes itself through its unique vertical configuration. This innovative setup involves the injection unit and clamping system arranged in a vertical orientation, making it particularly effective for specific manufacturing scenarios. The machine operates by utilizing gravity to assist in the molding process, where melted plastic material is injected downward into the mold cavity. This vertical orientation proves especially beneficial when working with insert molding applications, as it prevents the displacement of metal inserts during the molding process. The technology incorporates advanced features such as precise temperature control systems, automated insert placement capabilities, and sophisticated pressure monitoring mechanisms. The vertical configuration excels in producing components that require exceptional precision and consistency, particularly in industries such as automotive, electronics, and medical device manufacturing. The process is highly versatile, accommodating a wide range of materials including thermoplastics, thermosets, and various engineering polymers. With cycle times comparable to horizontal machines, vertical injection molding machines offer unique advantages in terms of floor space utilization and specialized application capabilities.