low volume plastic injection molding

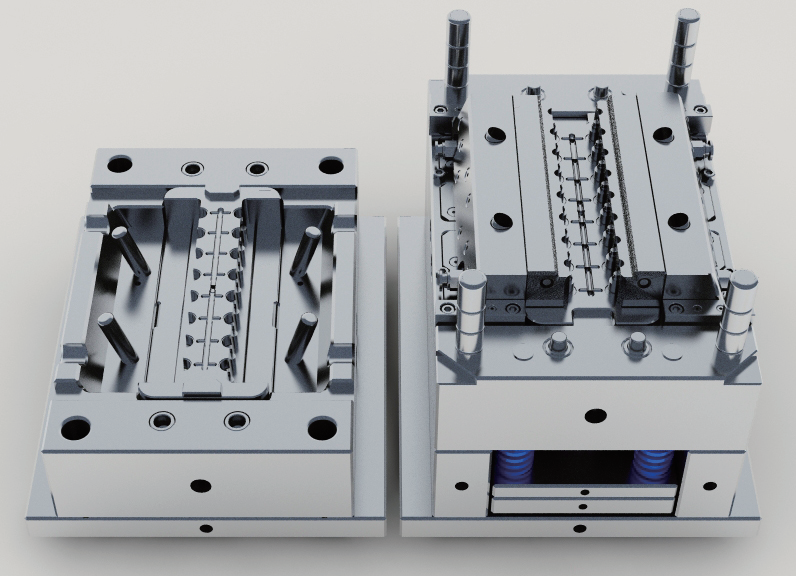

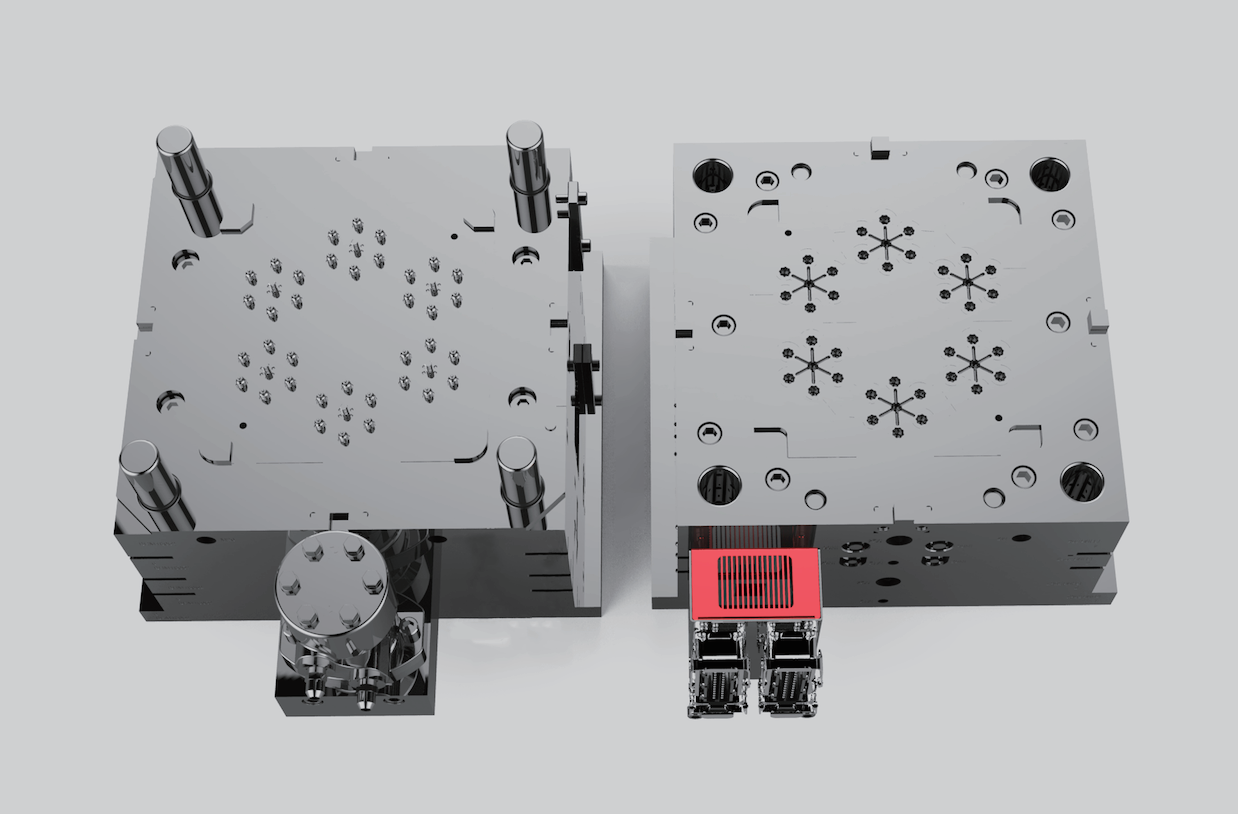

Low volume plastic injection molding is a specialized manufacturing process designed for producing smaller quantities of plastic parts with high precision and quality. This process utilizes sophisticated injection molding equipment but is optimized for production runs ranging from a few hundred to several thousand pieces. The technology incorporates advanced tooling systems that can be rapidly modified or adjusted, allowing for greater flexibility in design modifications and material choices. The process begins with the creation of aluminum molds, which are more cost-effective than traditional steel molds used in high-volume production. These molds are carefully engineered to maintain precise tolerances while accommodating various thermoplastic materials. The injection process itself is carefully controlled through computerized systems that monitor parameters such as pressure, temperature, and injection speed to ensure consistent part quality. This manufacturing method bridges the gap between prototype development and full-scale production, making it ideal for market testing, specialized applications, or products with limited demand. The technology also supports complex geometries and various surface finishes, while maintaining tight tolerances and structural integrity. It's particularly valuable in industries such as medical devices, automotive components, consumer electronics, and aerospace applications where quality cannot be compromised despite lower production volumes.