polycarbonate injection molding

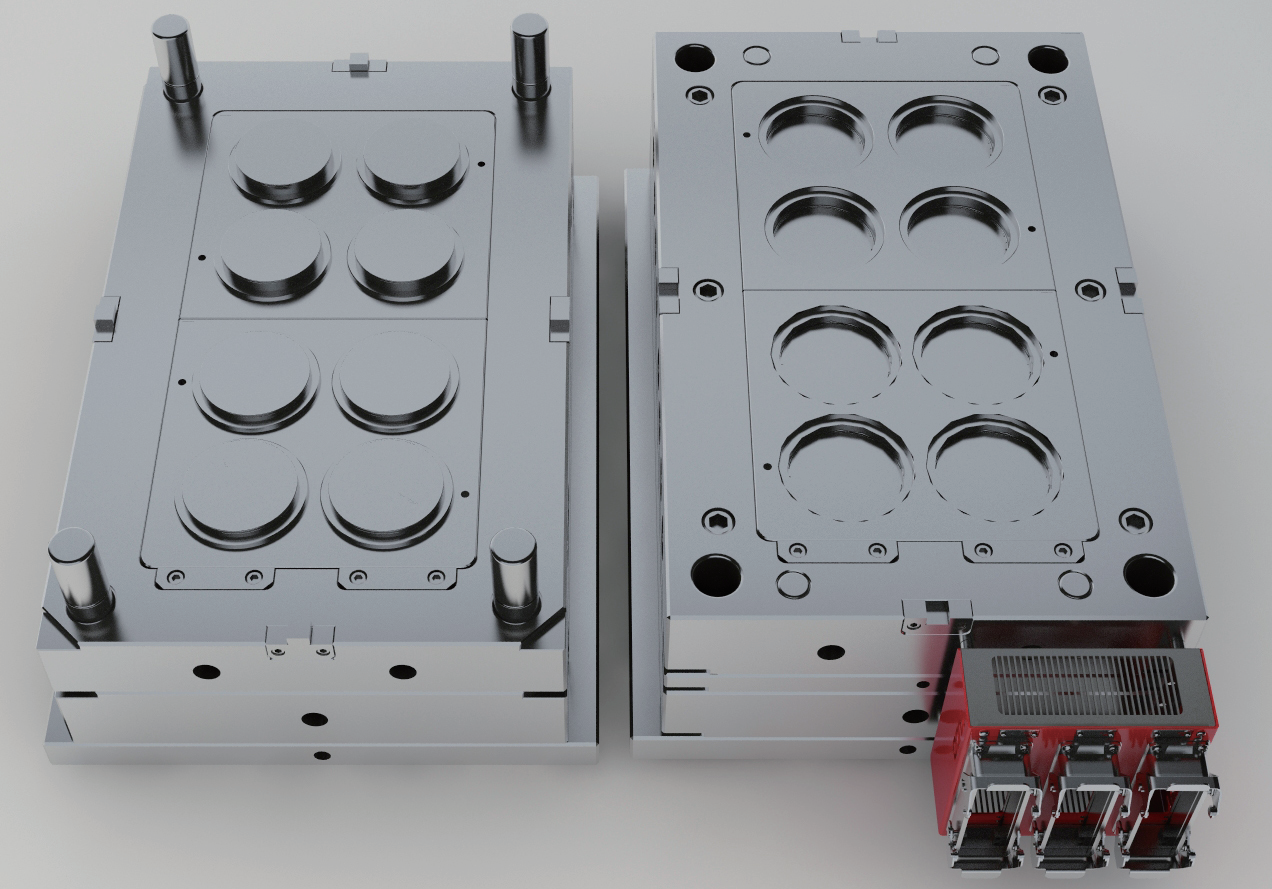

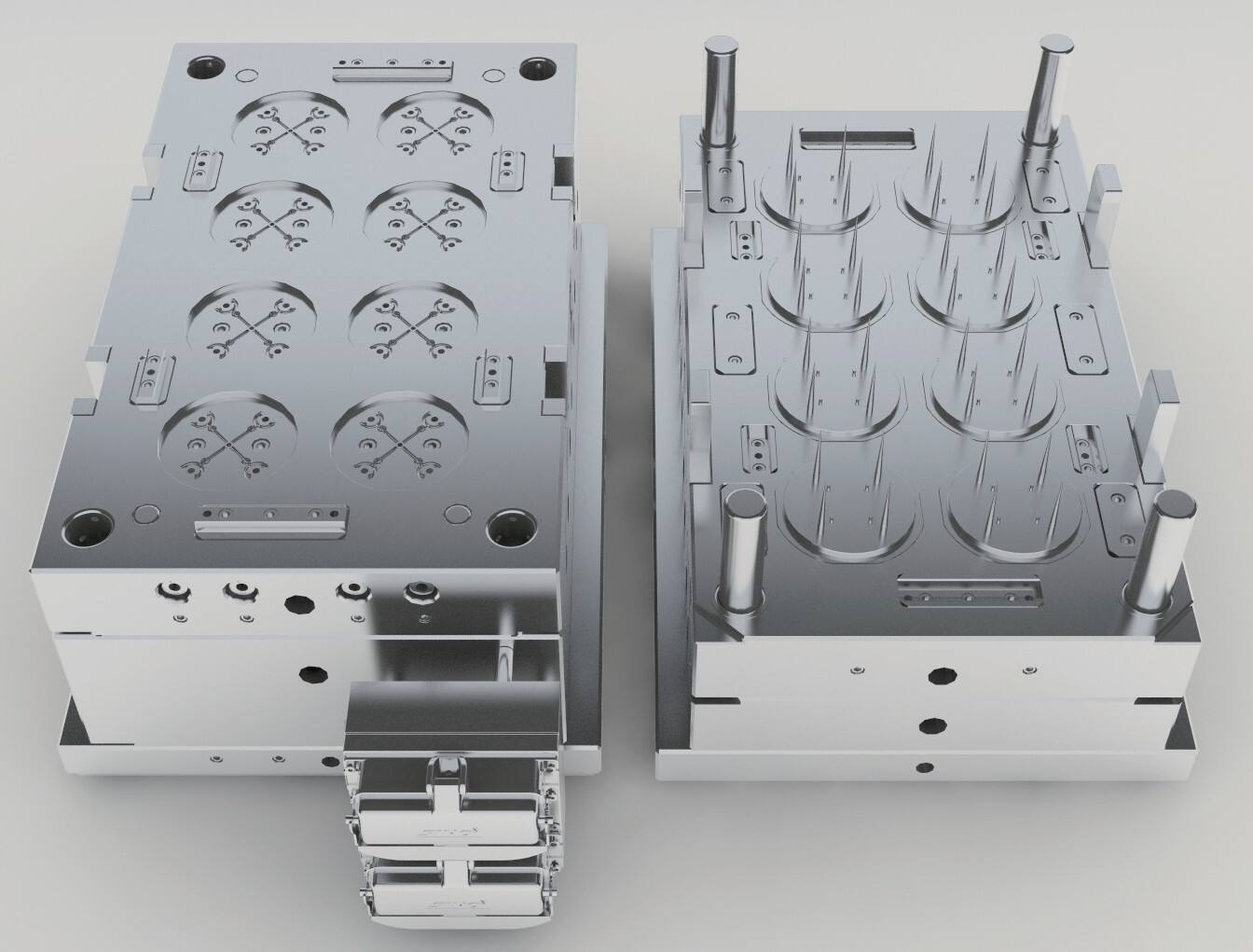

Polycarbonate injection molding is a sophisticated manufacturing process that combines the exceptional properties of polycarbonate materials with precise injection molding techniques. This versatile process involves heating polycarbonate pellets until they reach a molten state, then injecting the material under high pressure into carefully designed molds. The process stands out for its ability to create complex, durable parts with excellent optical clarity and impact resistance. The technology enables manufacturers to produce components with tight tolerances and consistent quality, making it ideal for both high-volume production runs and specialized applications. The process particularly excels in creating parts that require transparency, durability, and dimensional stability. Industries ranging from automotive and electronics to medical devices and consumer goods rely on polycarbonate injection molding for producing everything from safety equipment and medical components to electronic housings and automotive parts. The process also accommodates various surface finishes and textures, allowing for customization to meet specific aesthetic and functional requirements. Modern polycarbonate injection molding incorporates advanced features such as precise temperature control, automated material handling, and sophisticated cooling systems to ensure optimal product quality and manufacturing efficiency.