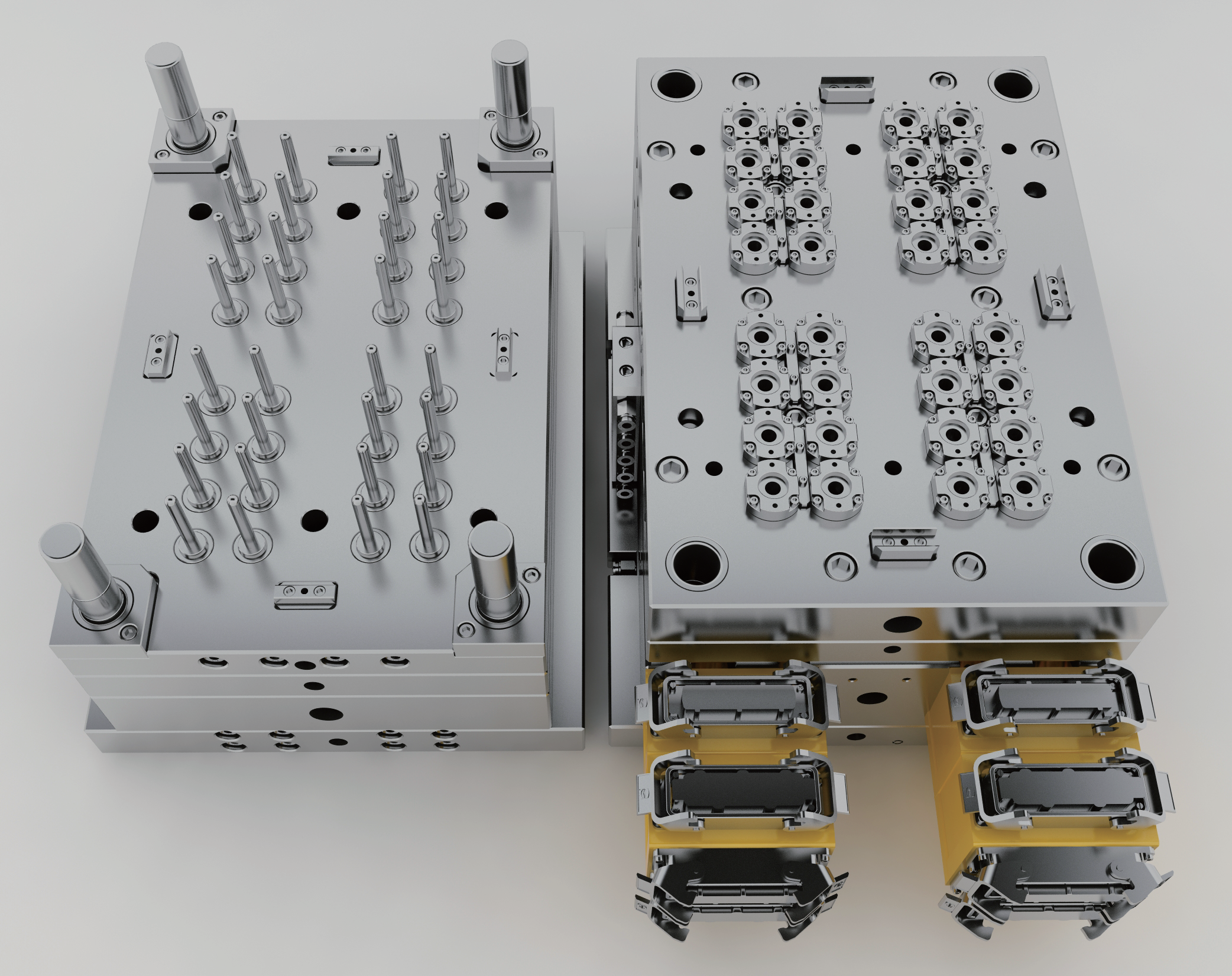

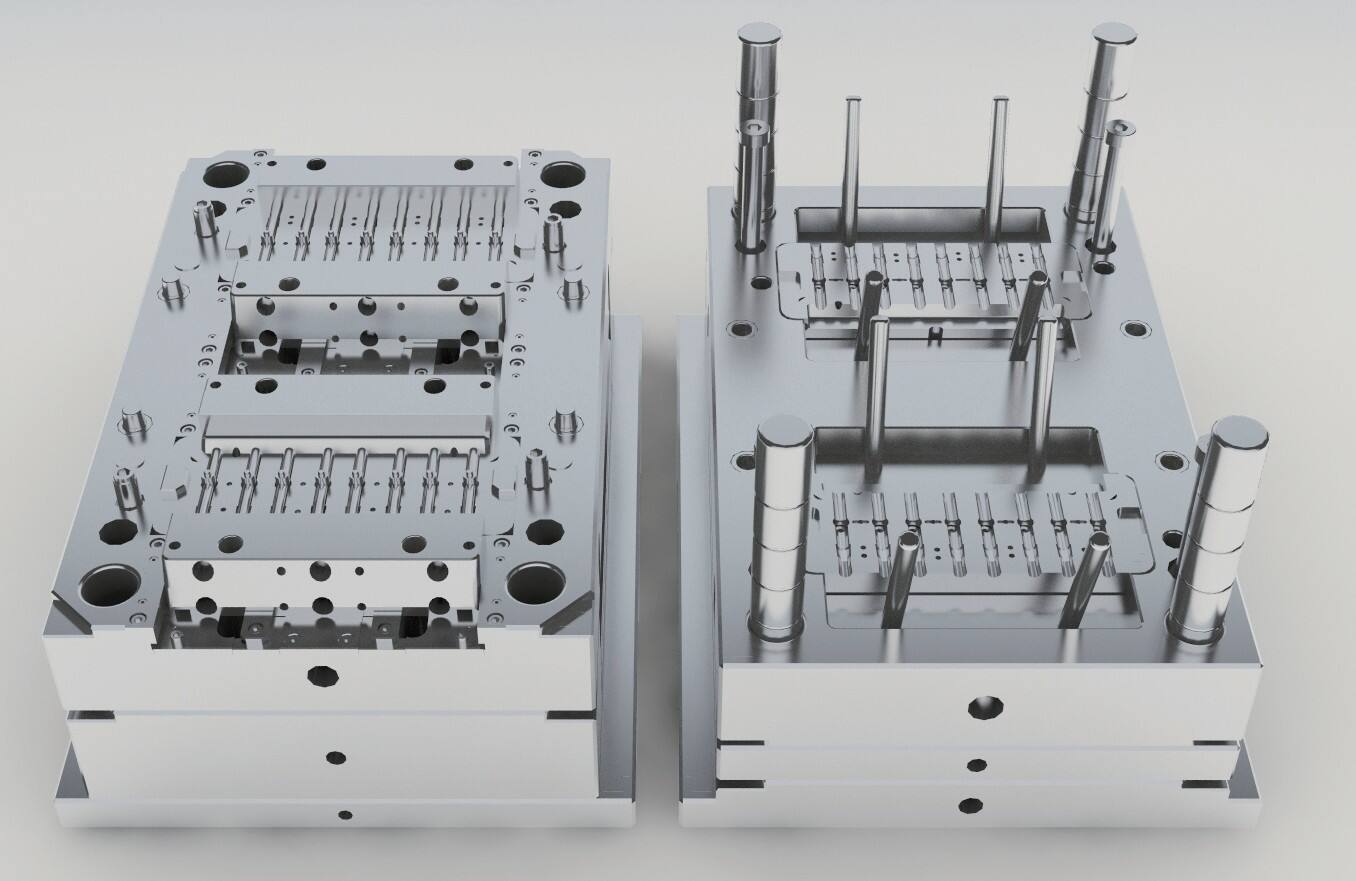

hard plastic molds

Hard plastic molds represent an essential component in modern manufacturing, serving as precision tools for creating consistent, high quality plastic products. These durable molds are engineered from high grade steel or aluminum, designed to withstand the intense pressures and temperatures of industrial plastic production processes. The molds feature intricate cavity systems that determine the final shape and characteristics of the molded products, complete with cooling channels that regulate temperature distribution and ejector mechanisms that facilitate smooth product removal. They are precision engineered to maintain tight tolerances and dimensional stability, ensuring each produced part meets exact specifications. The technology incorporates advanced features such as interchangeable inserts, multiple cavity configurations, and sophisticated venting systems to prevent defects. These molds are extensively used in automotive parts manufacturing, consumer electronics, medical devices, and household products, offering exceptional reliability and repeatability in high volume production scenarios. The design process involves sophisticated CAD/CAM systems, allowing for complex geometries and precise control over wall thickness, surface finish, and other critical parameters.