rapid injection molding prototyping

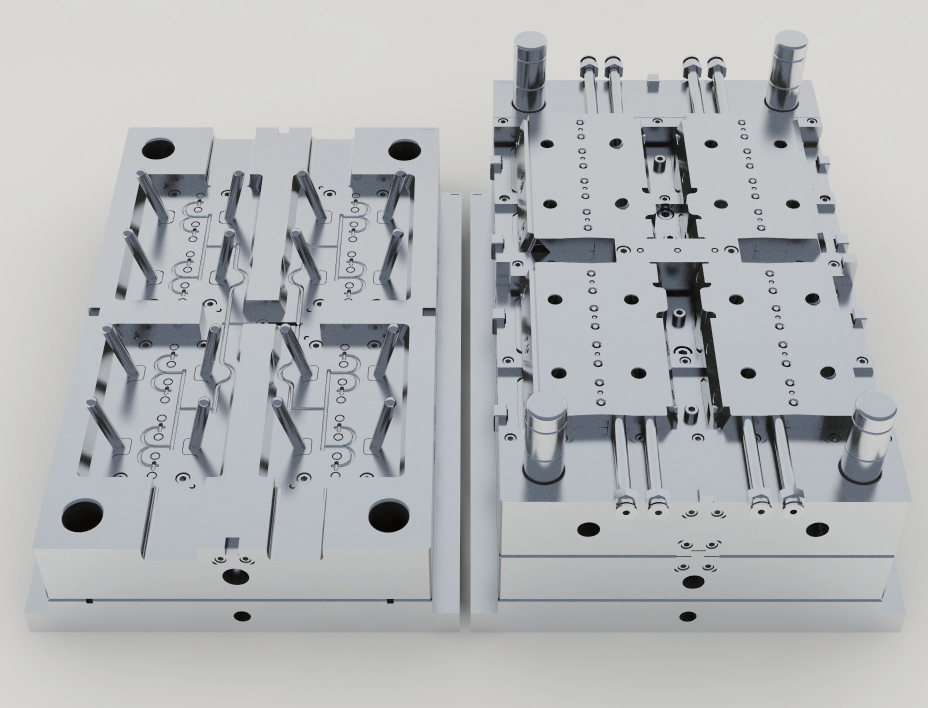

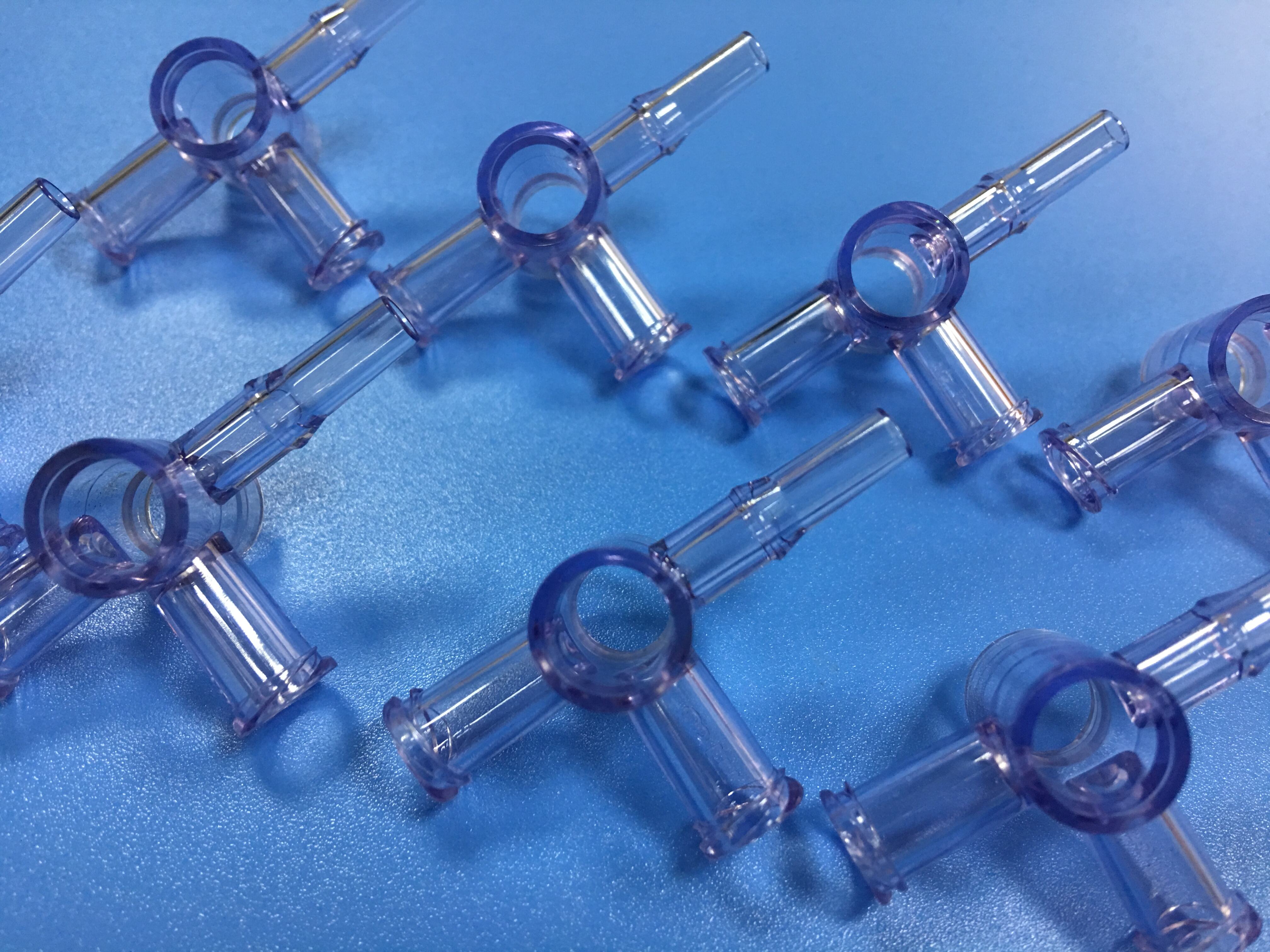

Rapid injection molding prototyping represents a revolutionary manufacturing process that combines the precision of traditional injection molding with the speed and flexibility of rapid prototyping technologies. This advanced manufacturing method enables the production of high-quality plastic parts and prototypes in a fraction of the time compared to conventional methods. The process begins with the creation of a detailed 3D CAD model, which is then used to manufacture aluminum molds through CNC machining. These molds are specifically designed for short production runs, typically ranging from 50 to 10,000 parts. The technology incorporates sophisticated cooling systems and precise temperature control mechanisms to ensure consistent part quality. What sets rapid injection molding prototyping apart is its ability to use production-grade materials, allowing manufacturers to test prototypes that possess the same physical properties as the final product. The process supports a wide range of thermoplastic materials, including engineering-grade resins, and can accommodate complex geometries with features such as undercuts, threads, and multiple cavities. This versatility makes it particularly valuable for industries such as automotive, medical device manufacturing, consumer electronics, and aerospace.